The challenge is real when it comes to using two thermal imaging NIR-B-2K cameras on a container glass furnace. One camera cannot see everything! Ideally, having two thermal NIR borescopes, one at each end, would be perfect, but resources are limited.

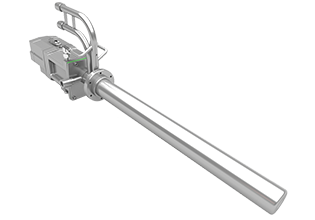

Historically, a camera was used above the throat to observe batch pile coverage, but it had limitations. However, with the introduction of thermal

NIR-Bs (Near Infrared Borescopes), the possibilities for improving operations and protecting assets have been enhanced.

A furnace operates and behaves differently at the start of a campaign when it's new compared to when it's old towards the end. In the beginning, achieving high Pull, NOx, and Energy levels is possible. However, as the furnace ages, the regenerators become a limitation.

The goal is to maximise pull, extend the furnace's life, minimize energy consumption and emissions, and ensure safety at all times. While key stakeholders may have different objectives,

NIR-Bs are implemented to support the entire furnace team.

AMETEK Land NIR-Bs are used on container glass furnaces for specific reasons, and having two of them is essential to improve operations significantly.

Here are the pros and cons of having two NIR-Bs located at the centre line of the furnace, one at each end:

NIR-B at Throat End (Bridge Wall)

Pros:

- Traditional CCTV location, which operators are familiar with.

- Best view of batch pattern, allowing observation of charging issues, doghouse and tuckstone wear.

- Good view of flames, enabling the detection of flame hitting the wall or crown and potential NOx reduction.

- Good view of port floors and potential target wall temperatures for reversal control.

Cons:

- Cannot see the bridge wall and the hottest parts of the furnace.

- Limited view of the crown.

- Above the throat can be hot due to significant radiation from forehearth flues.

NIR-B at Charging End

Pros:

- Maximum potential view of the refractory crown and true thermal profile.

- Can identify batch carry-over hitting the bridge wall.

Cons:

- Minimal view of batch pattern, as achieving an angle to see the batch will be between ports.

- Limited view of the flames, and burner alley can be dangerous when working adjacent to an operating burner.

- Risk of fire, and compliance with ATEX regulations may be required.

- At the end of the furnace's life, temperatures will be high.

In fact, using two

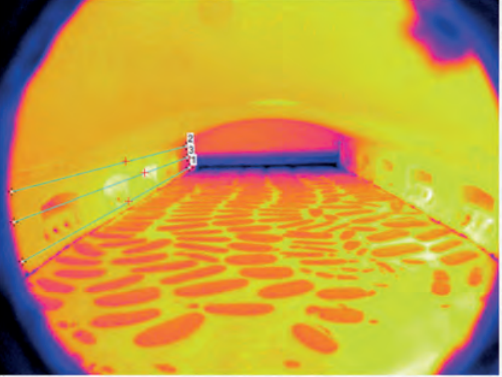

NIR-Bs can cover many details, including batch piles and coverage, and overcome the limitations of having NIR-Bs in just one location. The NIR-B cameras must be angled downwards for optimal performance.

Ultimately, temperature control is crucial, and two NIR-B cameras provide all the necessary details.

Container glass furnaces require precise temperature control to ensure optimal glass production.

NIR-Bs are designed to measure and monitor the temperature of the

glass in real-time. By using two NIR-Bs, operators can obtain temperature data from multiple points within the furnace, allowing for better temperature uniformity and control.

Safety and efficiency are paramount as glass furnaces operate at extremely high temperatures. The consistent temperature distribution is critical for both safety and energy efficiency. With two NIR-Bs, potential temperature variations or hotspots can be detected and corrected more effectively, reducing the risk of thermal imbalances and potential damage to the furnace structure.

Having two

NIR-Bs provides a level of redundancy. If one fails or malfunctions, the second one can continue to monitor and control the temperature, ensuring that production can continue with minimal interruption.

Optimization of combustion and energy reduction can be achieved by using NIR-Bs as part of the burner system in glass furnaces. With two NIR-Bs, operators can optimize the combustion process by adjusting the burner settings based on data obtained from both sensors. This leads to more efficient fuel consumption and better control of the combustion process, resulting in improved glass quality and production rates.

Quality control is key to reducing yields. Consistent temperature control directly impacts the quality of the glass produced. By utilizing two

NIR-Bs, glass manufacturers can ensure that the glass is heated and cooled uniformly, reducing the chances of defects and ensuring consistent product quality.

In conclusion, using two of AMETEK Land's NIR-Bs on container glass furnaces, enhances temperature control, improves safety, increases efficiency, and contributes to maintaining high-quality glass production.

Click here to learn more about the NIR-B-2K Glass Borescope