In aluminium extrusion, precision is not just a goal it is a necessity. From heating billets to quenching finished profiles, every stage of the process depends on accurate temperature control.

At

LAND, we support manufacturers in achieving this precision with advanced non-contact temperature measurement solutions tailored to the unique challenges of aluminium.

This blog highlights some of the key temperature control challenges in aluminium extrusion, and how LAND’s advanced non-contact temperature measurement solutions help optimise and control the process. It also includes insights from a customer who successfully implemented LAND’s technology to improve reliability, reduce downtime, and enhance product quality.

The Task: Billet Temperature Measurement

Aluminium billets, solid cylindrical blocks, are heated and pressed through a preheated die to form specific profile shapes. To ensure the final product meets strict mechanical and dimensional specifications, it is essential to monitor and control the temperature of the billet, the die, the press exit, and the quenching process.

Aluminium billets, solid cylindrical blocks, are heated and pressed through a preheated die to form specific profile shapes. To ensure the final product meets strict mechanical and dimensional specifications, it is essential to monitor and control the temperature of the billet, the die, the press exit, and the quenching process.

However, aluminium presents a unique challenge. Its surface properties change rapidly due to oxidation, and its high reflectivity makes standard pyrometers unreliable. These instruments struggle to compensate for the changing emissivity and produce consistent readings.

The Process: Aluminium Billet Temperature Measurement

Before extrusion, the billet must be heated to a specific temperature profile known as a taper to account for the heat generated during pressing. If the billet is under heated, it can damage the die, block the process, or result in poor quality products.

Non-contact temperature measurement allows for real time monitoring and control, helping to:

• Optimise the heating process

• Prevent wasted billets

• Avoid costly downtime and repairs

The Solution: Aluminium Billet Temperature Measurement

When billets move past the pyrometer’s field of view, their full temperature profile can be captured using an active threshold trigger. This enables continuous measurement from start to end.

Image: Billet temperature profiles, taken on passing billets in application

Image: Billet temperature profiles, taken on passing billets in application

If the billet is stationary, the

SPOT Actuator scans along its length, triggered by the heat of the billet itself, to measure the entire temperature profile.

Recommended Products:

•

SPOT+ AL

•

SPOT Actuator

Customer Experience and Benefits:

“The intelligent multimode application pyrometer SPOT+ AL / LT can easily be adapted, even by just aligning the pyrometer and choosing the working mode. In most cases no additional offset alignment is needed. This enables a highly reliable and continuous temperature measurement in billet profile temperature measurements in the process.”

______________________________________________________________________

The Task: Die Temperature Measurement

The die must be preheated before extrusion begins. If it is too cold, it can cool the billet, causing it to solidify and block the process. Rapid and accurate temperature measurement is essential to ensure the die is at the correct temperature before being loaded into the press.

The Solution: Aluminium Die Temperature Measurement

As the die is removed from the preheat furnace, its surface temperature can be measured using either:

•

A Cyclops C160L portable pyrometer

•

A SPOT+ M160 (FO) stationary pyrometer

These instruments use short wavelength technology, which reduces sensitivity to surface variations and ensures fast, reliable readings.

Recommended Products:

•

SPOT+ M160 (FO)

•

Cyclops C160L

Customer Experience and Benefits:

“The temperature measurement of each die before entering the press is essential for process control and to prevent any cold dies going into the process and creating blockages and process issues. The temperatures are clearly shown to the operators during the die handling process.”

______________________________________________________________________

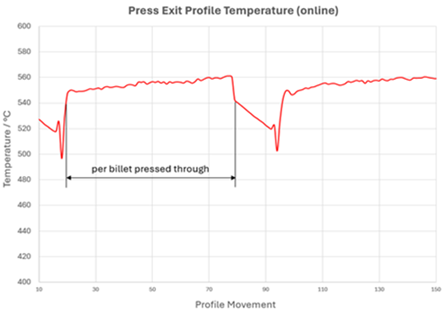

The Task: Press Exit and Quench Exit Profile Temperature Measurement

As the aluminium profile exits the press, typically at 500 to 600 °C, it must be monitored to control press speed and ensure the correct mechanical properties. After extrusion, the profile is quenched to rapidly cool it, which affects its hardness and resilience.

Additionally, thin or complex profiles can shift position as they exit the press, making continuous and accurate temperature tracking even more critical.

Accurate temperature measurement is needed at both the press exit and the quench exit to:

• Ensure proper cooling rates

• Maintain dimensional tolerances

• Achieve the desired material properties

The Solution: Aluminium Extrusion and Quenching Temperature Measurement

The

SPOT+ application pyrometer is used to measure profile temperatures as they move continuously. If profiles shift transversely, the

SPOT Actuator tracks them to maintain accurate alignment.

By activating the SPOT+ E mode (extrusion mode) and configuring the scan settings, operators can monitor both the press exit and quench exit temperatures. This also allows for real time calculation and control of the quench rate.

Recommended Products:

•

SPOT+ AL

•

SPOT Actuator

Customer Experience and Benefits:

“Reliable temperature measurement and process control makes sure the aluminium profiles have the required physical properties, surface finish, and precise dimension tolerances by the time it leaves the press and quench exit.”

______________________________________________________________________

Conclusion

Precise temperature measurement is the backbone of quality and efficiency in aluminium extrusion. From billet to die, and from press to quench,

LAND’s advanced pyrometers and actuators provide the data and control needed to keep the process running smoothly and the product within spec.