Engineers and technicians are typically highly qualified within their fields. They know the applications and processes in detail and provide continuous support to optimise them.

T

he engineers and technicians at

AMETEK Land know the customer processes and are specialists in the field of non-contact, infrared temperature measurement, making them a crucial part of the AMETEK Land team.

Have you heard statements like:

"This temperature measuring device is the right one because it can measure temperatures from 600 to 2000C"? Matching

non-contact temperature measuring devices to the challenges you are facing is difficult, that’s why with most of our temperature measurement technologies, our application support team discuss your requirements in detail before providing you with a quote, however many other businesses offer a one size fits all service and sell specialised equipment via shopping portals and E-commerce sites, but this isn’t always the best choice.

After you have initially identified a need for our temperature measurement technology, our team will visit your site to understand your requirements further and provide their advice on the best instrument for your application.

Starting with the temperature measuring range, this usually does not have to cover the entire process temperature range but should include the range in which the process is running (e.g. 800C +/- 100C). By specifying the temperature measurement range, the appropriate Infrared instrument can then be determined.

Another point to consider is whether a simple point temperature is needed, each application differs and depending on your requirements, you may need a standard point meausuring instrument such as our

SPOT Pyrometer or a more complicated thermal imaging system such as the

LWIR-640 for improving product quality and energy saving.

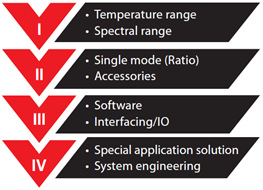

The typical selection process of a suitable Infrared temperature measuring device takes place in various steps, which are shown in figure 1.

Fig 1.

Pyrometer Selection Process

These along with many other specifications should be carefully considered and discussed in detail with an expert prior to selecting a non-contact temperature measuring device.

To discuss your temperature measurement challenges with a member of our team or to optimise your existing technology, click here