Sir William Herschel determined the relative energy of sunlight by using a simple optical prism and passing sunlight through it. The typical rainbow colours appeared and at the end of the red visible colour he used a thermometer to measure the temperatures and found that the temperature was rising. He concluded that the spectrum of the sunlight was continuing beyond the visible red light – he called this INFRARED.

Non-contact infrared temperature measurement

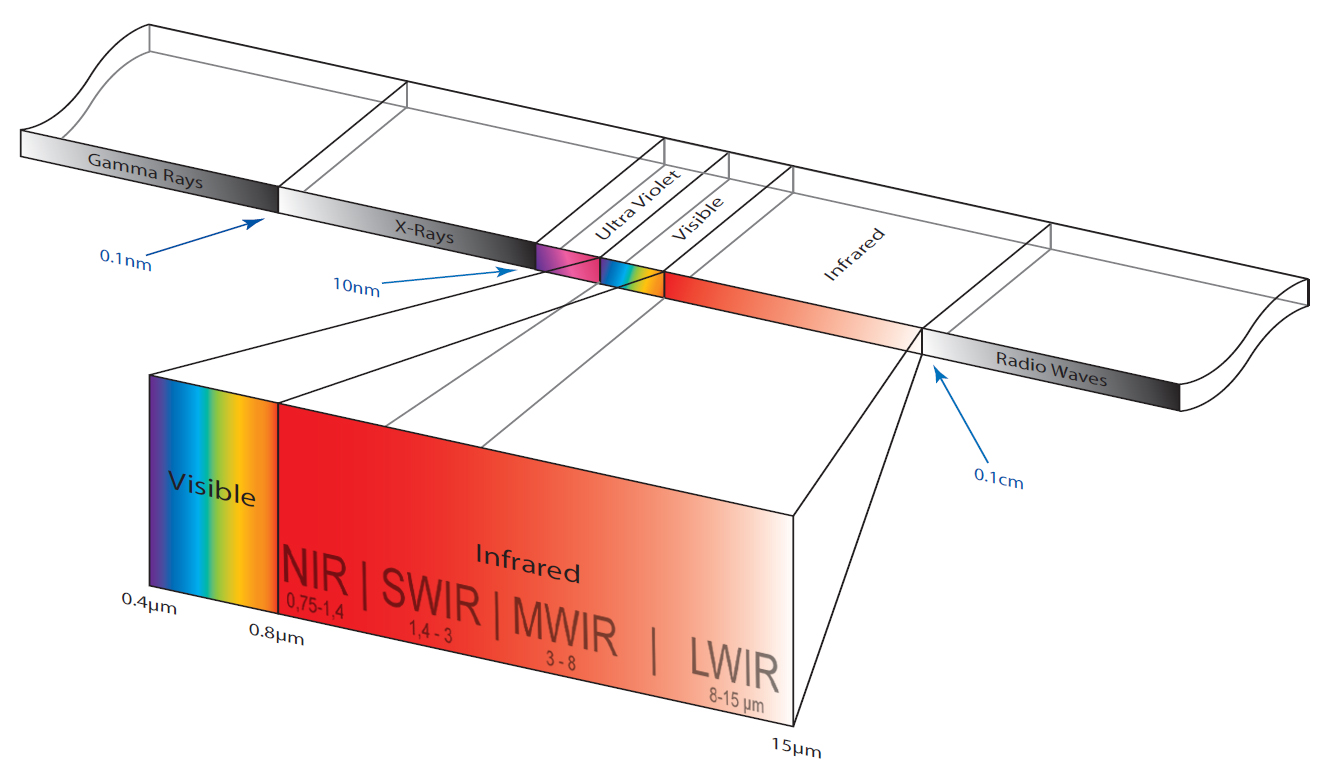

Non-contact infrared temperature measurement uses the infrared radiation emitted by objects at a certain temperature. While the whole range of infrared temperature measurement is in the wavelength range of 0.75 μm to 1000 μm, it is separated into different subranges (commonly used):

The main ranges for non-contact temperature measurement are the NIR, SWIR, MWIR and LWIR ranges covering wavelengths of 0.75 - 15 μm. It is therefore called “Thermal Infrared”. Some special devices are designed to work in the visible light range, for example at 550 nm.

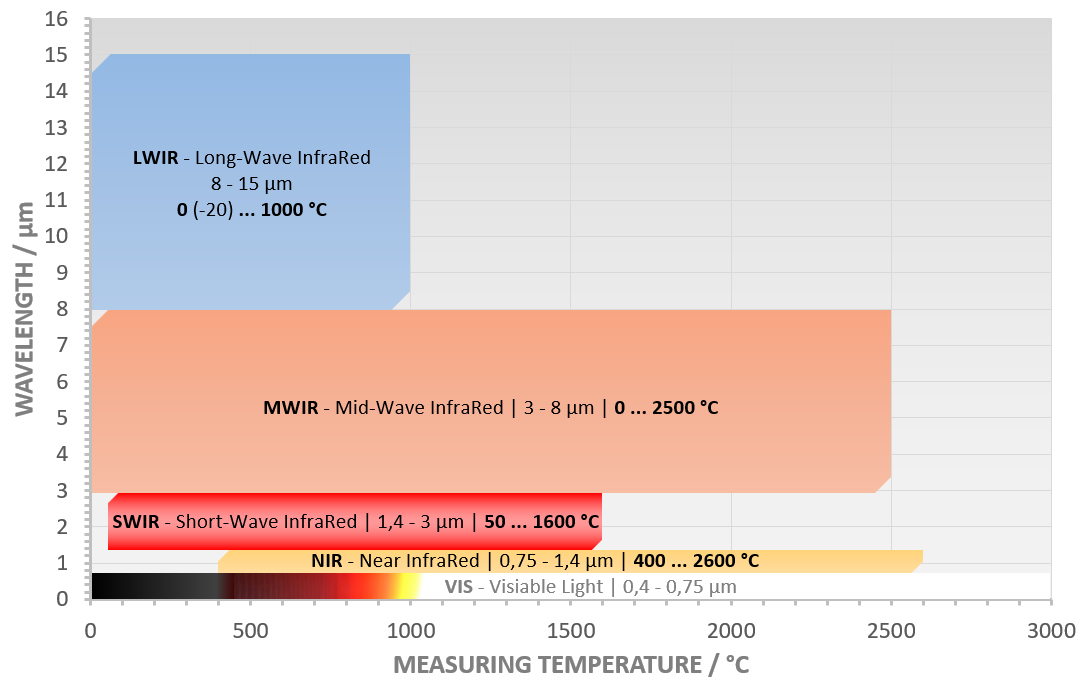

Following the Planck’s Radiation Law and the Wien's displacement law, typically with short(er) wavelength instruments, higher temperatures are measured. The lower the application temperature, the longer the wavelength (spectral response) of the instrument (pyrometer/scanner/imager) is – and vice versa.

The below diagram shows typical temperature ranges covered by different spectral responses of infrared radiation temperature measurement devices.

To choose the best instrument for a specific application – apart from critical application conditions – the process temperature is one of the main parameters determining the instrument wavelength required.

Commonly it is important to select the shortest possible wavelength of an instrument within the range to minimize the reading error due to changes in the measurement conditions, like the emissivity of the object to be measured.

These are not the only parameters and conditions to be considered when selecting the best instrument. If you would like further expert advice on the

non-contact temperature measurement system required for your specific industrial process/application,

please contact us.