Optical fibre preforms are the starting material for manufacturing optical fibres.

They are cylinders of optical glass which have the same composition and structure as the finished fibre but are typically around 100 mm in diameter.

The most common manufacturing method is modified chemical vapour deposition (MCVD) and can use either of two geometries. Inside vapour deposition starts with a silica tube and deposits the material on the inside wall. This allows precise control of the refractive index profile and is used for single-mode fibres, but it initially leaves a hollow tube. Outside deposition starts with a silica rod and deposits the material on the surface and is used for multimode fibres.

In both cases, a torch travels along the rotating substrate, locally heating it to a temperature in the region of 1600 °C. The reactants (typically a combination of silicon chloride, germanium chloride and oxygen) are deposited as a porous, sooty material on the surface.

Once the deposition is complete, the preform is heated to drive off hydroxyl ions which cause signal losses in the finished fibre, then further heated to 1800 °C to consolidate the soot into pure glass. A higher temperature of 2000 °C is needed for inside vapour deposition so that surface tension collapses the hollow centre to create a solid preform.

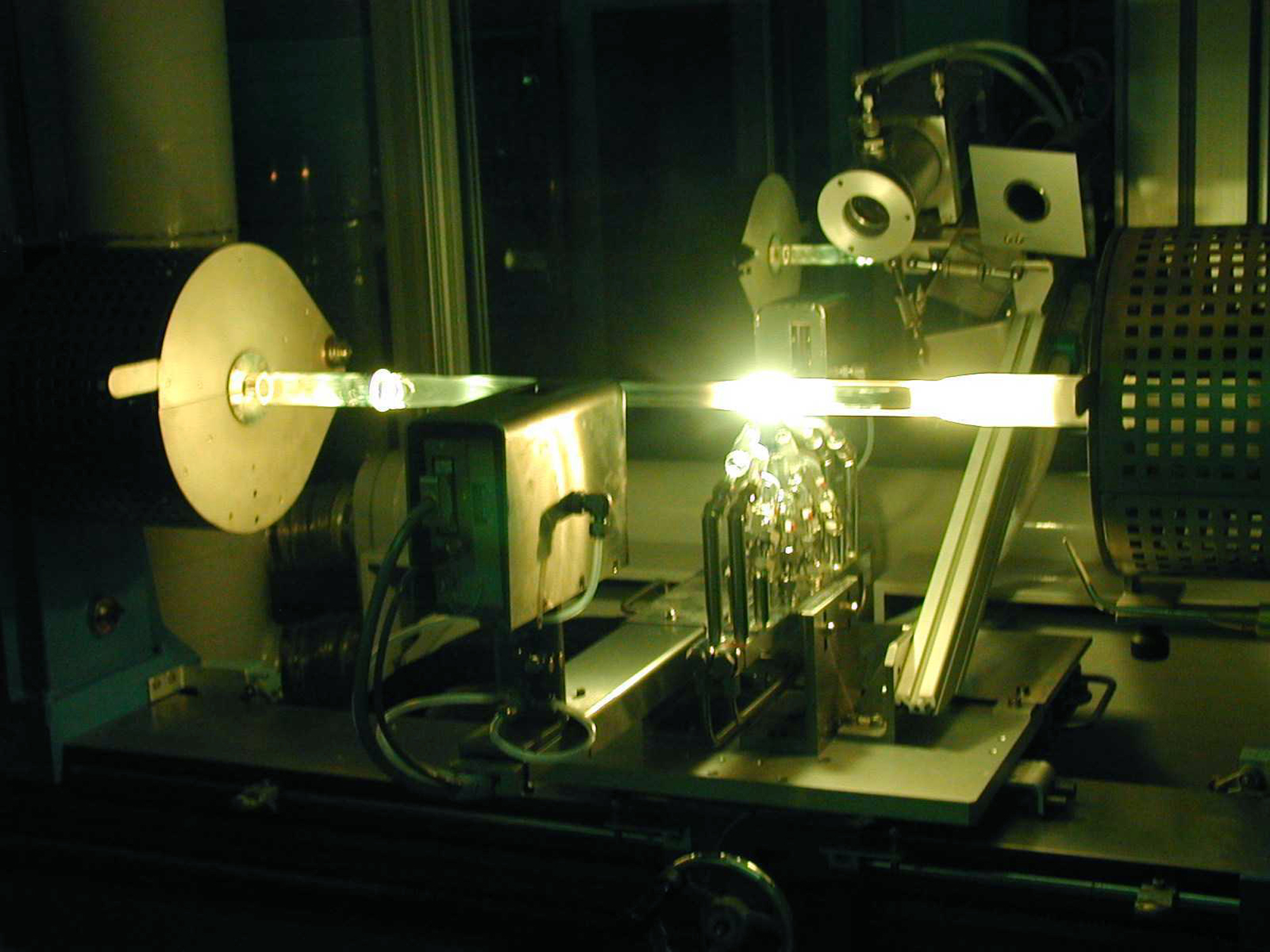

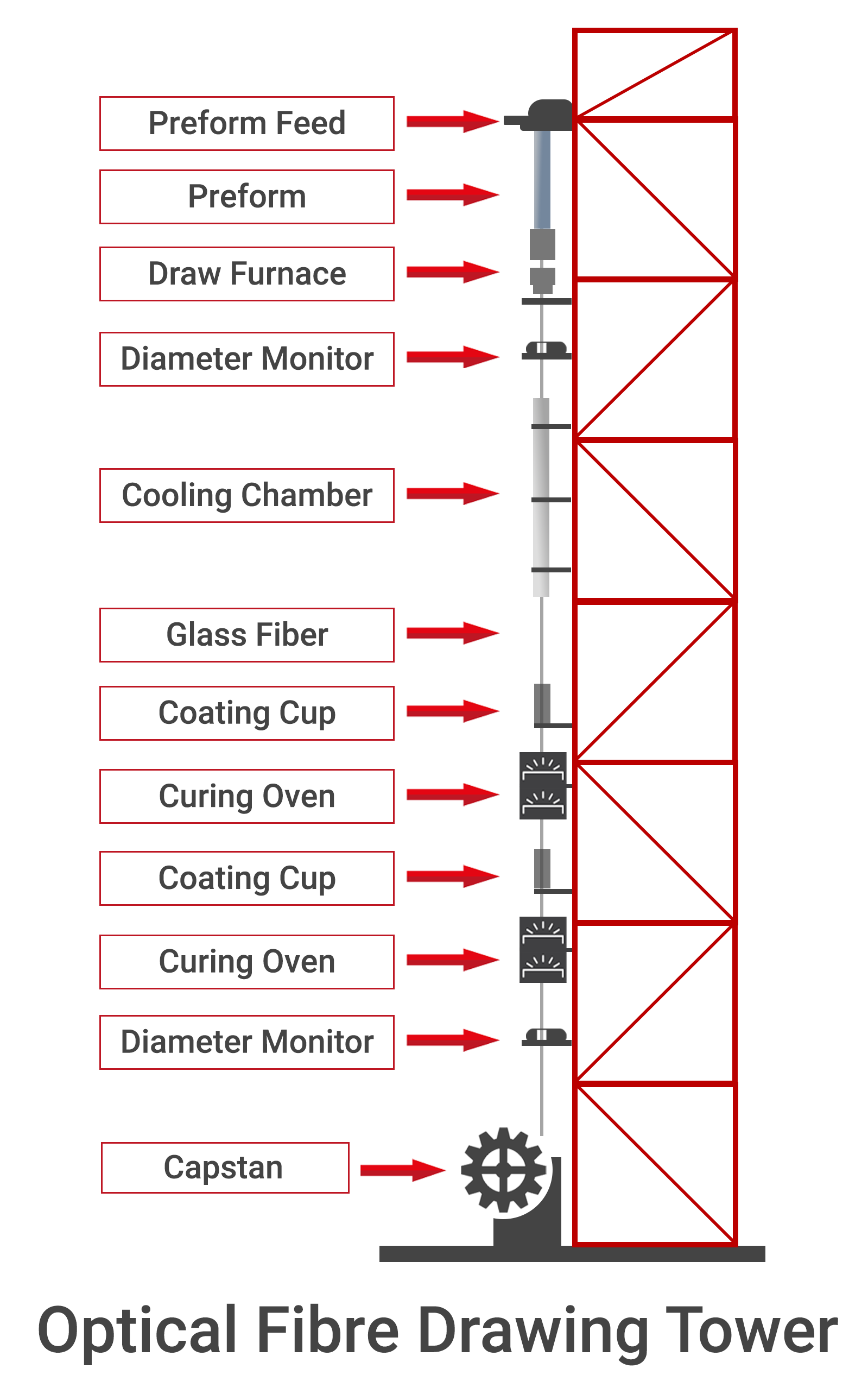

Once complete, the preform is moved to a drawing tower where the bottom part is heated above 2100 °C to soften it and allow the thin fibre to be pulled from it. Drawing speeds are typically above 10 m/s so many kilometres of fibre can be produced in a few minutes from a single preform.

Accurate temperature measurement and control is vital at all stages in the fibre production process and

LAND have pyrometers specifically designed for these measurements. The high temperatures involved mean it is impractical to use contact thermometers such as thermocouples, so these are ideal applications for infrared temperature measurement.

The new

VDT+ vapour deposition thermometer uses a specific wavelength in the 5 µm region to measure the preform temperature during vapour deposition. Glass is opaque at this wavelength and interferences from atmospheric gases and products of combustion are minimal. It has through-the-lens sighting and a narrow 100:1 field of view for precise optical alignment. A rugged and modular design ensures the pyrometer withstands harsh environments, particularly important in this application. The updated electronic design allows for fast, accurate, drift-free measurements to ensure a high yield. The flexible design has built-in signal processing, including signal averaging and a peak picker algorithm.

The

DTT drawing tower thermometer is designed for measurements in the drawing tower furnace. The thermometer uses a fibre optic head which allows it to keep the sensitive electronics away from the extreme temperature of the active area. It has a small field of view, with a target size of 4 mm at 450 mm, which allows to measure between the coils in an induction heated furnace, or sight down a narrow tube into the furnace. The 1 µm measuring wavelength minimises the errors resulting from uncertainties in the target emissivity.

Both

VDT+ and

DTT pyrometers allow accurate, reliable temperature measurements to ensure the highest quality optical fibre production.