As someone who is deeply involved in helping the petrochemical industry improve both safety and production yield, I know how crucial it is to optimise steam cracker furnaces.

Modern

steam crackers have many complex components, each offering opportunities for optimisation - from tube metallurgy to burner technology. Across all these areas, temperature measurement is key.

With over 75 years of expertise in temperature measurement,

LAND® is well-positioned to provide asset owners with the accurate, real-time tube temperature data they need This data, in turn, allows operators to make informed adjustments to the process, avoiding downtime and maximising production.

One of the biggest variables in traditional handheld tube metal temperature measurements (TMT’s) is the operator. Automating tube metal temperature monitoring with a fixed thermal imaging system removes this variability. This not only provides a much better understanding of temperature profiles within the furnace, but the repeatability and 24/7 data availability of a

fixed system is incredibly powerful. With hundreds of imagers installed globally, LAND has a proven track record in improving yield, safety, reliability, and efficiency.

To understand why accurate temperature data is so vital, it's important to consider the challenges of furnace operation. During operation, coke builds up inside the furnace tubes. This coke layer acts as an insulator between the hot flue gas and the cooler effluent stream inside the tube, causing the tube wall temperature to increase. As the coke layer thickens, the tube wall temperature continues to rise.

Operators must decoke the furnace before the tube wall temperature reaches its design limit. Operating above this limit significantly reduces the tube's lifespan and can create major safety concerns. Traditionally, operators have used a conservative decoking schedule to avoid exceeding the design limit. Alternatively, they might use differential pressure measurements (which indicate coke layer thickness) or manual tube wall temperature measurements to guide decoking.

However, decoking based on accurate, automated TMTs allows operators to run for longer periods before decoking is necessary. This approach maximises run length without compromising tube lifespan.

The

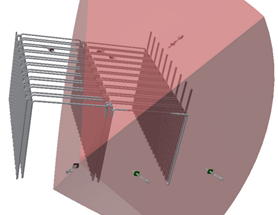

LAND experts provide valuable advice on camera selection and installation. This includes determining the optimal camera placement to maximise investment, achieved through a field of view analysis. This analysis considers practical and physics-based factors, giving the customer a clear visualisation of what they can monitor from any given camera.

LAND offer a range of

thermal imaging solutions specifically designed for

steam cracker furnaces. These include the

NIR-b-640-EX and

NIR-b-2K fixed borescope cameras, along with

ImagePro image and data processing software.

These tools are essential for effectively monitoring and optimising furnace performance.

For more details on the benefits of using thermal imaging to optimise steam cracker furnaces, check out LAND’s comprehensive application note