Since 1947, LAND has been a leading manufacturer of precision measuring equipment, providing essential non-contact temperature measurement and combustion monitoring solutions across vital industries including glass, steel, energy, and cement production.

I'm thrilled to highlight a significant achievement that underscores the value our technology brings to the glass sector: in the past six years, we've seen over 200 installations of our

NIR-b thermal imaging systems specifically designed for glass furnace applications. This technology delivers calibrated, traceable temperature measurements directly comparable to the industry-standard

Cyclops C100L portable thermometer, a tool relied upon globally for furnace monitoring.

This accomplishment is truly remarkable. We started with a clean slate, initially concentrating on furnace temperatures, where the NIR-b thermal imagers offer a far more advanced alternative to the visual cameras traditionally employed.

Back in 2017,

LAND and leading glass manufacturer

Encirc jointly won the Innovative Solution category at the Glass Focus Awards. Our real-time, in-furnace thermal imaging using Near Infrared Borescope

(NIR-b-Glass) has proven instrumental in optimising furnace operations and combustion efficiency. This marked our initial step towards decarbonising oil or natural gas-fired glass furnaces, even if we didn't explicitly use the term "decarbonisation" at the time.

Building on the expertise we've gained since then, alongside the launch of a

portable version of our acclaimed NIR-b thermal imaging solution, we are now positioned to make a substantial contribution to reducing CO₂ emissions and enhancing energy efficiency within the glass industry.

When I took on the role of Global Lead at

LAND for the glass segment in 2019, I was immediately struck by the complexity and dynamism of the global glass industry. Major players possess extensive experience in producing container glass for beverages, bottles, and flat glass for construction and automotive applications. Glass is a ubiquitous part of our lives, and the market is vast, encompassing numerous production sites worldwide.

I quickly realised that our success hinges on several key factors: product quality, the value our solutions provide, operational efficiency, and customer satisfaction built on a foundation of trust. By fostering strong collaboration, we have not only met these challenges but consistently exceeded expectations.

The

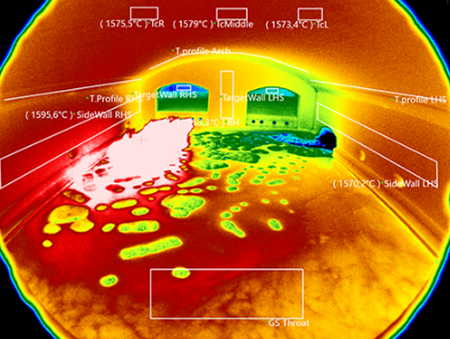

NIR-b thermal imaging camera has been a revelation, and I am now a firm advocate for infrared technology in furnace applications. This calibrated and precise instrument provides a thermal view that effectively replaces a staggering three million portable pyrometers, as a single NIR-b high-definition camera. Coupled with our expertise in image interpretation, we have empowered our customers to achieve significant improvements in their daily monitoring processes.

This instrument offers considerable benefits for furnace monitoring, including supporting thermocouple verification, pinpointing cold and hot spots, optimising combustion by identifying hot spots in the flame to reduce emissions and energy consumption, and determining the batch line to ensure balanced furnace operation and the production of defect-free glass.

Over the past four years,

LAND has driven progress through strategic initiatives focused on product quality, manufacturing efficiency, and market competitiveness. A key achievement has been fostering innovation, particularly in software with

ImagePro Glass, enabling precise batch line and pile management. We're also developing AI-based batch line control and new glass surface measurement concepts.

Our

portable NIR-b has been invaluable for thermal surveys, revealing significant improvements in combustion efficiency and decarbonisation. Many now see it as the starting point for decarbonising various furnace types.

Looking ahead, we're excited to further introduce our advanced

Pneumatic Auto-Retraction System (LPAR) at upcoming

glass industry exhibitions. Compatible with all of our NIR-b and MWIR-b models, it serves several industry segments, including glass.

We also understand that on-site innovation requires support. To address this, we offer comprehensive training programs for thermal image interpretation and

ImagePro software utilisation.

The evolving glass industry faces significant emissions reduction challenges. The choice between gas and electric furnaces is complex, requiring careful consideration of application needs, costs, energy efficiency, and environmental impact. Long-term investments should prioritise renewable energy sources where feasible.

Collaboration with sustainability experts and the adoption of Industry 4.0 technologies like SCADA and predictive tools are crucial. Sharing best practices and leveraging government incentives can further support the transition to sustainable practices.

Our

NIR-b-2K thermal imaging technology is central to this transition. Ultimately, data and digitalisation, powered by technologies like the NIR-b-2K, are indispensable for decarbonising the glass industry. They enable real-time monitoring, predictive maintenance, energy optimisation, supply chain efficiency, and carbon accounting, facilitating the shift towards more sustainable operations, including hybrid furnaces.