Monitoring tube wall temperatures (TWT) provides the maximum level of catalyst tube life to ensure energy efficiency and productivity. High temperatures inside the furnace can cause expansion of the tubes, or even catastrophic tube failure, along with creep damage, coke formation and process flow problems.

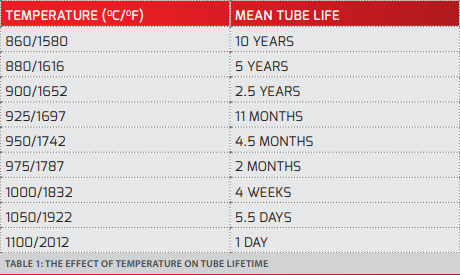

The cost of not properly managing TWT can be extremely high, since the effect on tube life can be significant. At levels of as little as 20 °C (36 °F) above the design temperature, the lifetime of the tube may be halved, with higher temperatures having an even more dramatic impact (see Table 1).

Having to rebuild a 400-tube reformer can cost millions in materials alone, while the impact of lost production can also be significant. Current data places a typical rebuild cost at more than £7 million ($9.2 million), or £14 million ($18.4 million) when labour and lost production is taken into consideration.

Unsurprisingly, many plants err on the side of safety when setting operating temperatures, to reduce the risk of this expensive tube damage. However, if the plant is run too conservatively in order to prevent tube overheating, it will not achieve full efficiency.

At low TWT levels, the production output is decreased. A reduction of 10 °C (18 °F) below the design temperature, for example, results in a 1% productivity efficiency loss that may translate to millions of dollars in sales. It is, therefore, critical to find and maintain the optimum temperature to deliver production efficiency while preventing damage to the tubes.

Read more about the benefits in our new

Steam Reformer Tube Wall Temperature Measurement Guide