The Gold Cup pyrometer by AMETEK Land is a widely used reference instrument for measuring tube wall temperatures in industrial applications, especially in the refining and petrochemical industry. However, using this tool requires some practical tips to ensure accuracy and safety during temperature surveys. Here are some useful tips for using the Gold Cup to measure tube wall temperatures:

- It's crucial to ensure that classroom training is provided to anyone using the Gold Cup for the first time. The training should cover the instrument's basic principles, operating procedures, and safety precautions. Generally, more advanced users will be interpreting the data, so the team collecting the data do not necessarily need full training on how to interpret and analyse the data obtained from the pyrometer.

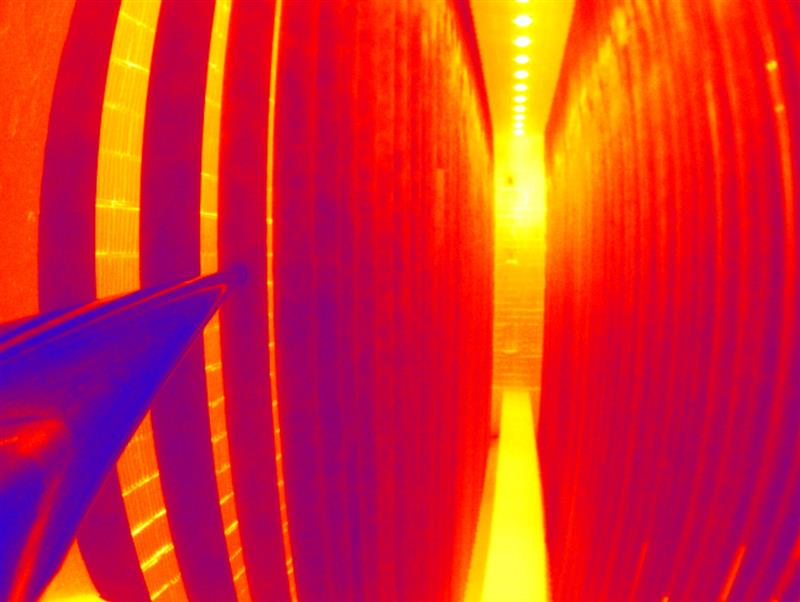

- Before a survey is conducted, practice sessions with the water inlet/outlet connected to the probe are advised to get used to its length and weight. The probe's length is typically 3 meters, and it can be quite heavy with the cooling water flowing. Thus, users should get familiar with the probe's handling to prevent accidents, damage to the fired heater and Gold Cup.

- Before arriving to site to conduct a temperature survey, check all water fittings for leak tightness to ensure they are secure and tight. Loose fittings can result in safety hazards because the Gold Cup may not be receiving the volume of cooling water it needs. Also check water pressures at the measurement locations before the survey is necessary to ensure that the instrument can function correctly. End-users often check water pressures away from the peep doors but find water pressures at the upper levels are below minimum requirements. The Gold Cup pyrometer requires a constant flow of cooling water to prevent damage to the detector.

- Thorough planning of the survey route and preparing documentation in advance can help to streamline the data collection and analysis process. Users should plan the measurement locations, take notes on the survey conditions, and record the data obtained from each measurement point. This documentation can help in identifying any issues and analysing the results to produce reference values for future surveys.

- Last, users should be assigned specific roles during a survey. E.g. user one is responsible for the gold cup contacting the tube and shouting contact, user two is responsible for holding and inserting/retracting the probe itself, and user two is responsible for holding the handheld unit and recording times and values.

Using The Gold Cup Pyrometer requires careful attention to detail, and following these practical tips can help ensure accuracy and safety during temperature surveys. By incorporating these tips into their measurement procedures, users can obtain reliable data for correcting pyrometer and thermal imager measurements, which is crucial in the petrochemical industry's steam methane reformers and steam crackers.

Click here to learn more about The Gold Cup Pyrometer