Rotary kilns play a pivotal role in various industries, including cement, lime production, iron ore pelletisation, waste incineration, and more. These cylindrical furnaces, lined with refractory stones and slightly tilted, continuously process materials as they rotate.

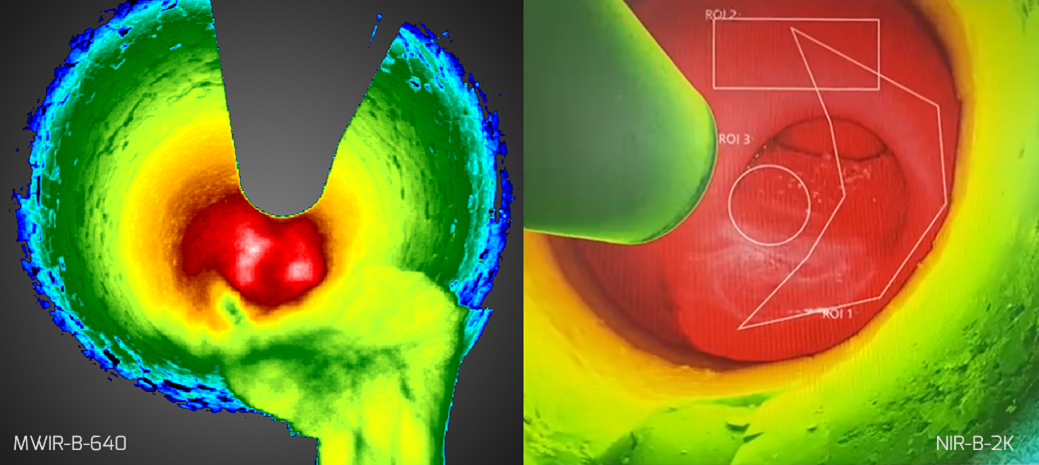

Material is fed into the cold end and transported through gravity and rotation to the hot end, where the burner operates. The processed material exits at the burner end and is typically conveyed further. Figure 1 depicts thermal images captured from inside rotary kilns using AMETEK Land's

NIR-B-2K and

MWIR-B-640 advanced thermal imaging systems.

Figure 1

Continuous rotation subjects the lining to stress and erosion, necessitating continuous monitoring and repair to detect defects, critical refractory breaks, or, in the worst-case scenario, kiln failure. Additionally, the bending and possible torsion of the furnace tube during rotation can damage and break lining bricks, which must be repaired, often involving the pouring of lining material. Otherwise, refractories need replacement during scheduled maintenance.

Early detection and localisation of such defects result in cost savings, reduced downtime, energy conservation, and enhanced safety for rotary kiln operations and the surrounding environment.

Early Hot-Spot Detection in Rotary Kiln Applications

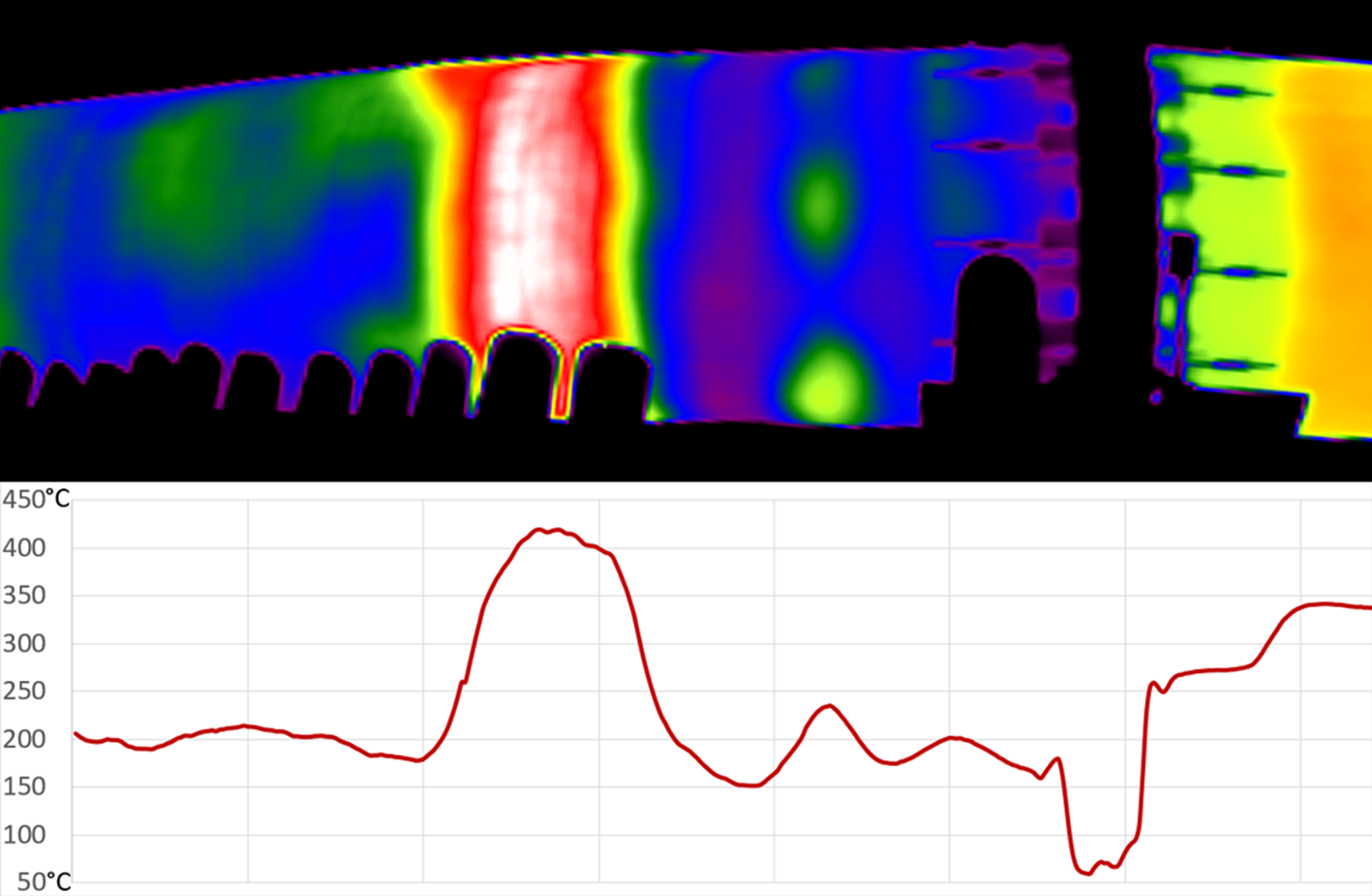

Figure 2

Measuring the kiln tube surface temperature using contact temperature measuring devices like thermocouples is impractical. Local pyrometers struggle to identify emerging or critical hot spots in the entire image. Thus, continuous, and full-area temperature monitoring of the kiln shell is imperative. Given the kiln's continuous rotation, both IR line scanners and thermal imagers are suitable for 24/7 hot-spot and condition monitoring of the rotary kiln's outer shell. Detecting critical hot spots early ensures safe kiln operation, reduces energy losses, and minimises emissions in energy-intensive processes.

IR Line Scanners for Rotary Kiln Shell Monitoring

AMETEK Land's market-leading

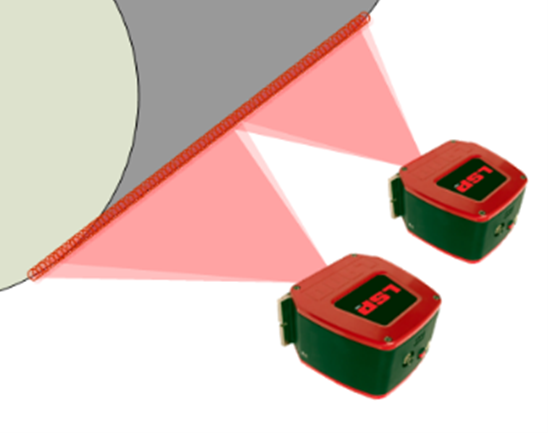

LSP-HD IR line scanners are widely employed in global industries and rotary kiln applications for monitoring the outer shell temperature, providing high-resolution thermal images and a continuous thermal map of the kiln. These compact line scanners offer highly homogeneous and high-accuracy thermal images. Installed to view the rotating kiln with an 80-degree scan angle, they sample 1,000 points along a single line at industry-leading scan speeds of up to 150 Hz, creating a complete thermal image of the shell temperature and identifying any aberrations (see Figure 3).

Figure 3

For long kilns, multiple scanners can be cascaded (see Figure 4).

AMETEK Land's proprietary Landscan software (see Figure 5) consolidates data from these scanners to provide a comprehensive view of the kiln temperature.

Figure 4

Figure 5

The scanner-based monitoring systems incorporate tire slip detection using rugged proximity switches to ensure tire movements remain within acceptable limits. Optional position sensors enable the

LSP-HD's Landscan controller to calculate and display kiln tire slip measurements alongside the kiln temperature, further reducing the likelihood of refractory damage (see Figure 6).

Figure 6

Determining the thickness of the internal refractory lining based on the outside surface temperature of the kiln is possible in some installations. However, this calculation involves numerous unknowns, including surface emissivity, heat transfer variations, material temperature differences, and burner flame impacts. These factors must be considered when estimating lining thickness.

Advanced Thermal Imaging for Rotary Kiln Shell Monitoring

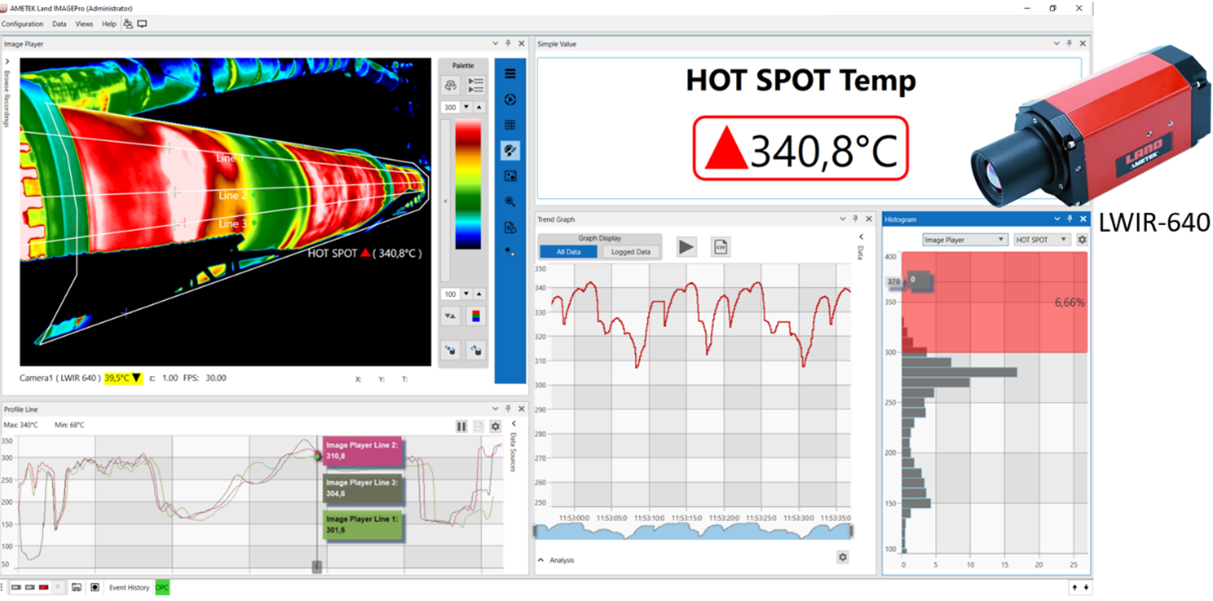

Figure 7

Figure 7 showcases the advanced

IMAGEPro thermal imaging and processing software paired with an

LWIR-640 industrial thermal imager in a rotary kiln application. Up to 16 thermal imagers can be combined with one server installation, providing continuous furnace hot spots and condition monitoring of the rotary kiln 24/7. Each imager offers more than 300,000 camera pixels, each fully radiometrically calibrated for accurate temperature readings.

Industrial accessories and enclosures enable reliable camera operation in all temperatures and weather conditions, including hazardous areas, if required. The system is remotely accessible, providing real-time data, pre-alarming, and alarming to operators throughout the plant. Event-triggered data capture, including temperature data and video recordings, can also be configured.

Continuous thermal imaging in rotary kiln applications facilitates early detection of critical hot spots and deviations from normal operating conditions, ensuring safe kiln operations, reducing energy consumption, minimising emissions in energy-intensive processes, and ultimately curbing costly repairs and downtime.

For tailored measurement solutions to optimise cost savings, process safety, and efficiency, please contact our global sales offices, applications, and service engineers.