In the realm of industrial measurement and control processes, the utilisation of thermal imaging cameras and systems has been on the rise. These advanced devices offer high-resolution thermal images, containing millions of camera pixels and operating at impressive frame rates.

However, the challenge lies in effectively extracting temperature data from these images and integrating it into the process control systems. In this blog post, we explore the process of extracting temperature data from thermal images and videos, as well as the interfaces and connectivities that enable seamless integration with process control systems.

Extracting Temperature Data from Thermal Images and Videos:

Extracting Temperature Data from Thermal Images and Videos:

Traditionally, infrared non-contact temperature measurements in industries were carried out using

pyrometers and

scanners, providing readings at specific points or along a line/profile. Nowadays,

thermal imaging cameras and systems are increasingly being employed in industrial processes, generating vast amounts of data due to their high pixel resolution and frame rates. For instance, the AMETEK Land

NIR-B-2K thermal imager can create nearly 5 GB of data per minute when operating at full pixel resolution and frame rate.

To make sense of this abundance of data, regions of interest (ROI) are employed to extract the essential temperature measurements. These ROIs allow for the output of minimum or maximum temperatures or the mean temperature of selected camera pixels. Such data are then continuously monitored, captured, and further processed, serving as vital inputs for process control.

Interfaces and Connectivities for Process Control Systems:

The

AMETEK Land smart thermal imaging product family offers a range of imaging solutions, catering to diverse industrial temperature measurement requirements. Let's explore the different interfaces and connectivities provided by these innovative thermal imagers:

Camera Integrated Webserver:

Equipped with a camera integrated webserver, these thermal imagers offer multiple I/O options, allowing autonomous use or easy integration into new or existing process control systems. The webserver provides secure access, control, and setup of the camera, facilitating remote access via a standard browser. On-board analog and digital I/O can be configured through the webserver for seamless process integration and control.

Customised Integration:

All

AMETEK Land thermal imagers and systems come with a Software Development Kit (SDK) as an option, offering communication routines that enable seamless integration into customised software, databases, and control systems. This flexibility allows for tailored solutions that meet specific application requirements.

Advanced Thermal Imaging and Process Control Software:

T

he

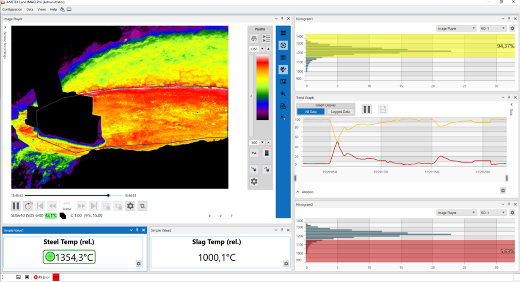

IMAGEPro thermal imaging software package empowers users with complete camera control for up to 16 imagers, facilitating process monitoring and data processing. In addition to digital and analog I/O modules, data communication can be accessed through protocols such as Modbus/TCP, TCP/IP, or OPC/UA, enabling bidirectional communication between process imagers, the IMAGEPro software, and process and plant control systems. Furthermore, application dedicated softwares, such as the

IMAGEPro-AM (Asset Monitor) software enables long-term data trending and analysis, particularly in critical vessel monitoring applications.

In conclusion, harnessing the power of smart thermal imagers and their integration into process control systems opens new avenues for efficient and accurate temperature measurements in industrial processes. With a range of interfaces and connectivities available, including camera integrated webservers, customised integration options, and advanced thermal imaging and process control software, users can leverage these innovative tools to enhance process safety, efficiency, and cost-effectiveness.