In this blog, I will explain how the NIR-B-2K thermal imager could reinforce the Cyclops C100L handheld, portable pyrometer temperature measurements in glass furnace operations.

The establishment of global standards governing emissions reducing the CO2 footprint, and today’s inadequate measurement processes are materially impacting the glass manufacturing industry. There is an increased focus on emission control and energy consumption, and to date, the E.U and UK have taken the lead on curtailing glass furnace emissions. The United Kingdom, for example, introduced several layers of legislation, including new rules setting goals for reducing the CO2 footprint and NOx emissions by 2050.

Key features of the furnaces include adequate insulation, good sealing to minimize air leakage, excellent heat recovery from regenerators, a well-designed doghouse and charging system, and an accurate control system.

Temperature measurements are becoming more and more important for the energy efficiency and operations of glass furnaces to achieve these new emission and energy goals and the fast-approaching deadlines that come with it.

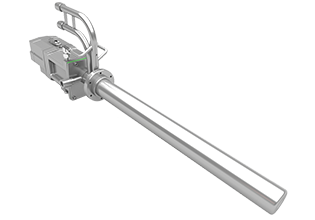

The Cyclops C100L is one of the most widely used and respected portable pyrometers in the world. It is used to measure the crown temperature during the reversal cycle when the flame is not present. It is also used to make a once per shift measurement across or between the port arches (depending on the furnace type).

The Cyclops C100L is one of the most widely used and respected portable pyrometers in the world. It is used to measure the crown temperature during the reversal cycle when the flame is not present. It is also used to make a once per shift measurement across or between the port arches (depending on the furnace type).

The target wall on the regenerator is seen as being a good indicator of gas temperature, so the Cyclops C100L is used to measure temperature here too. Rugged and reliable, it can be fitted with a heat-resistant cover and measures between 550-3000°C (1022-5432°F).

For routine spot checks and shooting optical profiles through peep holes for port arch or crown measurements , the industry standard Cyclops C100L (2F) is in common use offering repeatable, reliable and calibrated traceable temperature measurement.

Key benefits of using Cyclops C100L:

- Measures from a clearly defined area

- Measures a small area from across the glass melt tank

- Wavelength of operation is filtered to ‘see through’ furnace combustion gas

- Fully serviceable by AMETEK Land.

- Maintains calibration and stability in hostile environments

What steps should you take to minimise systematic errors with Cyclops C100L?

- Using the Cyclops L pyrometer to measure a surface temperature, of which the emissivity is well known and set to the correct emissivity within the instrument.

- Not having any obstructions in the optical path, like dust, steam, obstacles, dirty optics, emissivity changes, low viewing angles or background reflections.

- Using the Average or Peak temperature measuring mode to eliminate some of the errors.

- Clean the protection window before use.

- A systematic approach to measurement, choose your target, set the focus, set the mode (continuous, peak, or average). Point and shoot record the reading you see in the viewfinder. (Do not go hunting unless you are surveying an area).

- Store the Cyclops in its protective case when not in use.

- An annual calibration and/or certification ISO 17025, combined with preventative maintenance, will ensure optimal operating performance from your temperature measurement systems, improving the accuracy of your measurement capability and meeting required national and international quality standards.

Why to combine the NIR-B-2K optical temperature measurements?

The NIR-B-2K is used for continuous temperature monitoring and recording of the refractory inside a glass tank offering repeatable, reliable, and calibrated, temperature measurements. The NIR-B-2K thermal imaging camera provides over 3 million continuous measurement points for asset protection, air ingress and capturing the optical profiles with a crystal-clear picture.

The NIR-B-2K is used for continuous temperature monitoring and recording of the refractory inside a glass tank offering repeatable, reliable, and calibrated, temperature measurements. The NIR-B-2K thermal imaging camera provides over 3 million continuous measurement points for asset protection, air ingress and capturing the optical profiles with a crystal-clear picture.

As the NIR-B-2k uses the same wavelength and filters as the industry leading Cyclops C100L portable pyrometer, the data is directly comparable.

This is real comparable data measurements when flames off supporting virtual thermocouple comparisons and reinforcing the measurement of the Cyclops for hot spot determination made by operators every day.

How can we measure and visualise the flame length and path in a Glass Melt Tank?

The NIR-B-2K Borescope whilst providing continuous temperature monitoring of refractories, also provides a thermal crystal-clear visual image inside the glass tank and visualisation of flames and or flame heat distribution. This allows the system to monitor and alarm if there is flame impingement which is very important on Oxy fuelled furnaces. The AMETEK Land Image Processing Software provides an integration function which reveals true flame intensity, offering an insight into the efficiency of combustion, flame length optimisation and NOx generation.

Additionally, the new IMAGEPro Software V2 with glass extension is providing a batch coverage function including:

- Batch line monitoring and batch carryover.

- Batch transit time and temperature of the blanket.

- Batch velocity vectors using time-lapse.

- Batch charger optimisation and troubleshooting.

The move to Oxy-fuels and fuel conversion could be a step associated to thermal imaging on furnace operations no matter the technology, or it could be to optimize the combustion at first and even if the NIR-B-2K is NOT the overall solution, this is a tool to consider in the decarbonisation tool box.

The move to Oxy-fuels and fuel conversion could be a step associated to thermal imaging on furnace operations no matter the technology, or it could be to optimize the combustion at first and even if the NIR-B-2K is NOT the overall solution, this is a tool to consider in the decarbonisation tool box.

For example, float glass processes have a residence time of up to 3 days. When quality deteriorates at cold inspection then it may take that length of time to recover or longer if we have to find the source or the root cause.

The idea is to create thermal images with fixed NIR-B-2K where pictures can be analyzed by all specialists and experts in the glass team and could see the same images for practical similar conclusions.

An additional route is to use the thermal imager as transportable for in-thermal surveys in a float furnace (through all existing peep holes) to reinforce the benefits of the existing fixed locations for the NIR-B-2K (or simply reinforced visual inspection). In this case, the Cyclops C100L is still the first step to correlate temperatures for hot spot locations.

In conclusion, the potential benefits of the NIR-B-2K include:

- Identifies sources of parasitic air which when repaired

- Identifies thermal profile and/or furnace in-balance

- Identifies potential locations for static NIR B in future

- Validate CFD models

- Optimises flame coverage

- NOx reduction

- Confirm any in-balances

- Identifies blockages/damage

- Potentially recover pull and extend furnace life

Click here to find more about the NIR-B-2K

Click here to find more about the Cyclops C100L