In the demanding world of copper smelting, even incremental improvements in metal recovery translate to substantial gains in profitability and resource efficiency. The challenge lies in accurately separating valuable copper matte from the slag, a byproduct of the smelting process.

Traditional, manual methods are often imprecise, leading to significant copper losses and increased waste. The LAND

Slag Detection System (SDS), originally proven in the steel industry with over 200 global installations, is also well suited to liquid copper matte and slag measurements.

The SDS is based on a mid-wavelength infrared (MWIR) imager operating at 3.9 µm. This wavelength was chosen because it is free from spectral features in a typical industrial atmosphere. Water vapor, carbon monoxide, carbon dioxide, methane and other hydrocarbons have no significant spectral absorption or emissions at this wavelength. The MWIR wavelength also reduces the visibility of metal fumes and other fine particles when compared to measurements made with visible light, since these particles have dimensions smaller than the wavelength.

The key to the measurement is the difference in emissivity between the bright metal and the dull slag. Emissivity is the property of a material which determines its efficiency in absorbing or emitting electromagnetic radiation. The theoretical limits are a black body which absorbs all of the radiation falling on it and has emissivity of 1.0 and a perfect reflector which absorbs none of the incident radiation and has zero emissivity. Real-world materials have emissivities between these values, though an infrared calibration furnace can be designed to have an emissivity greater than 0.99 and an optical mirror can have emissivity in the region of 0.02.

In a steel application, the metal has an emissivity around 0.4 whilst the slag has emissivity in the region of 0.75. Therefore, the

SDS can readily distinguish between the two because the slag emits more infrared radiation and appears hotter than the metal. This fundamentally transforms slag detection by introducing a digital and automated approach, replacing the inherent limitations of manual methods which rely on the skill of the operator. Automating the end of the pour is faster and more reliable than manual control and allows for more repeatable steel production.

In most cases, the system’s default settings work reliably, but the user can readily tune the sensitivity by adjusting the detection thresholds for both metal and slag. The tap ends automatically when the proportion of slag in the field of view rises to 30%. Using an automated SDS has been shown to reduce slag carryover by as much as 25%.

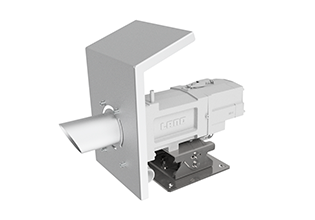

A proof-of-concept demonstration in a copper application was carried out at a facility in Europe. A

LAND imager and positioned to view the stream of molten material leaving the vessel.

The transition from steel to copper smelting presents a unique set of challenges. Copper melts at a lower temperature than steel, and the matte-to-slag ratios, as well as the mechanism of the pour, differ significantly. The core objective remains the same: to maximize copper recovery while minimizing waste and enhancing operational safety.

Over 20 taps were viewed during the test and data were recorded for subsequent analysis. Figures 1 and 2 show the

SDS system’s ability to distinguish slag from matte during slag separation, to provide a visualization of the pour for the operator, and to quantify the relative amounts of matte and slag. The differentiation is caused by the different emissivities of slag and matte. The lower emissivity of the matte makes the imager register a lower temperature because it emits less infrared radiation at any given temperature.

Fig. 1

Fig. 1 -

Thermal images from early (left) and late (right) stages of the tap

The differentiation can be seen clearly in Fig. 1 where the left-hand image was taken early in the tap and shows pure slag, with an indicated temperature between 1190 °C and 1260 °C. The right-hand image was close to the end of the tap: the matte is clearly visible and appears cooler, with red and blue colours indicating a temperature below 900 °C . It is important to note that the actual temperatures of slag and matte are very similar: the apparent temperature difference is a consequence of the different emissivities.

Figure 2 shows the operator interface. The image of the tap uses isotherms to visually distinguish slag from matte. The display shows instantaneous and cumulative amount of each during the pour, based on the relative areas or red and green in the image. The system’s sensitivity can be adjusted by changing the programmed tap temperature and the emissivities of the matte and slag.

Beyond improved recovery, the

SDS significantly enhances operator safety. By using thermal imaging technology, the system eliminates the need for direct visual observation of the molten material. Operators can monitor the slag-to-metal stream via a computer display with a colour palette selected to maximize the contrast between slag and molten metal. This remote monitoring capability significantly reduces the risk of exposure to high temperatures and fumes.

Fig. 2

Fig. 2 - Screenshot of SDS during slag separation. Slag is red, matte is green

The system's reliance on mid-wavelength infrared technology plays a crucial role in its effectiveness. This technology is highly sensitive to the subtle emissivity differences between slag and matte, enabling precise differentiation even under challenging conditions. Operators can accurately assess the quality of the pour and make informed decisions about when to stop, minimizing copper loss and optimizing the process.

Moreover, the improved efficiency and accuracy of the

SDS lead to significant cost savings. By minimizing copper loss and optimizing the smelting process, facilities can achieve higher yields and reduce operational expenses. The combined benefits of enhanced recovery, improved safety, and increased efficiency position the SDS as a vital tool for modern copper smelting operations.

Derek Stuart and Ryan Silkworth will present these results at the Extraction 2025 conference in Phoenix, Arizona in November 2025.