The glass industry continuously evolves, seeking innovative solutions to improve furnace operations, efficiency, and product quality. At the forefront of these advancements is LAND's state-of-the-art technology: the Near Infrared Borescope (NIR-B-2K-Glass) and the IMAGEPro V2 software.

Together, these tools provide glass producers with unparalleled insights and control, aligning with Industry 4.0 standards.

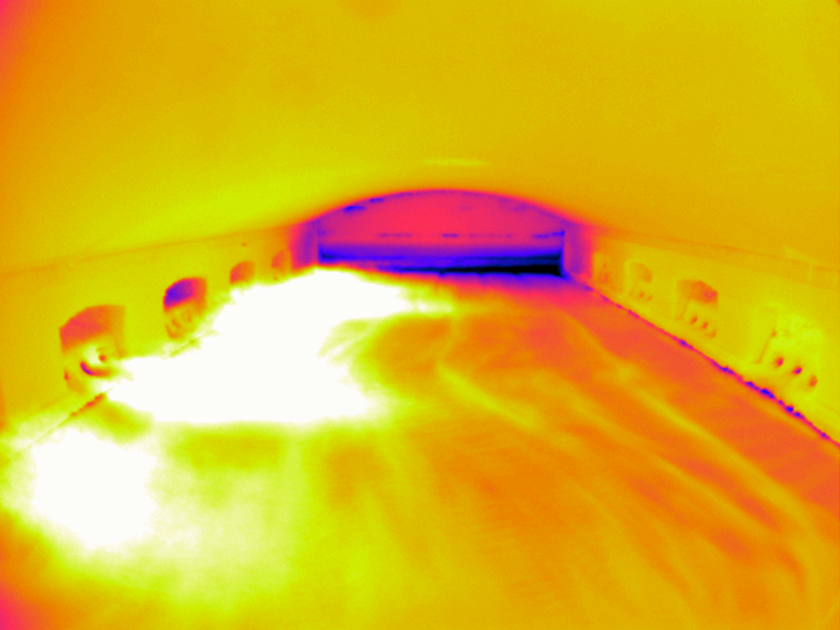

The NIR-B-2K-Glass: Precision and Detail

The

NIR-B-2K-Glass is a high-definition thermal imaging system that captures true-temperature radiometric images within a glass furnace. With its 3 million pixels, it delivers continuous and precise temperature measurements 24/7, crucial for maintaining consistent furnace operations. Key areas such as the crown, ports, and burner blocks can be monitored in real-time, ensuring optimal performance and identifying potential issues before they escalate.

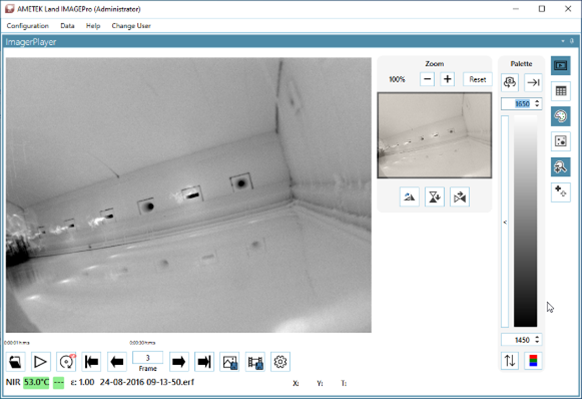

Comprehensive Furnace Monitoring with IMAGEPro V2

The

IMAGEPro V2 software complements the NIR-B-2K-Glass by offering detailed analysis and visualisation of thermal data. This integration facilitates several core functions essential for furnace efficiency:

• Melt Tank and Furnace Control:

By capturing optical thermal profiles, the system allows for precise temperature-based automatic reversals, optimizing furnace operations and reducing manual interventions.

• Campaign Life Extension:

Continuous temperature monitoring of critical components, including the crown, ensures efficient use of assets and prolongs their operational life.

• Production Efficiency:

The software tracks batch transit time and coverage, providing valuable data to improve throughput and glass quality.

• Energy and Emission Management:

By optimising flame patterns and combustion efficiency, IMAGEPro V2 helps achieve significant energy savings and reduce emissions.

Practical Application: Monitoring Batch Coverage

The batch coverage feature of

IMAGEPro V2 maps the thermal image into a grid, pinpointing specific spots for detailed analysis. Operators can set alarms for cold batch areas, capturing images for quality assurance and troubleshooting. This process involves:

• Setting Up:

Proper installation and configuration of the system to define the batch coverage grid and flames threshold.

• Defining Criteria:

Establishing desired coverage parameters such as percentage of glass surface coverage and uniformity requirements.

• Capturing Images:

Activating the system to capture images of the glass coverage during furnace operations.

• Analysing Data:

Using the software to visualise and measure batch coverage, identifying any imbalances or areas needing adjustment.

• Adjusting Furnace Settings:

Making necessary adjustments to furnace parameters based on the analysis to ensure optimal batch coverage.

• Continuous Monitoring:

Regularly capturing images and analysing data to maintain ongoing furnace balance and performance.

Optimising Oxy-Gas Furnaces

For oxy-gas furnaces, the

NIR-B-2K-Glass offers additional benefits. It assists in thermocouple verification, identifying air ingress, and optimising combustion processes. The ability to monitor thermal profiles continuously supports proactive maintenance and quick response to potential issues, aligning with Industry 4.0 standards.

Operators can utilise profile lines for continuous thermal profiling, highlighting areas that require maintenance or optimisation. The massive data capture capability of the NIR-B demands real-time analysis and long-term trend monitoring, essential for preventive maintenance and process improvement.

Conclusion

LAND

Conclusion

LAND's

NIR-B-2K-Glass and

IMAGEPro V2 software represent a significant leap in glass furnace technology. By providing detailed, real-time thermal data and comprehensive analysis tools, they enable glass producers to optimise furnace operations, enhance product quality, and achieve energy efficiency.

Embracing these advanced technologies ensures that glass manufacturers can meet the stringent demands of modern production environments and maintain a competitive edge in the industry.

Click here to learn more about the NIR-B-2K-Glass