Tiny increases in the percentage of recovered metals can have a huge impact both on the profitability and resource efficiency of facilities that process slag to recover a range of metals. Increasingly, we’ve been asked to install our ‘Slag Detection System’ in non-steel applications where parameters vary from the processes the system was originally designed for (detecting steel in slag during primary steelmaking).

Fortunately, the challenges have been overcome by our software team by increasing the system’s versatility, which has helped us in a number of successful installations globally. This flexibility is now built into our standard offering.

The example below shows how a copper cathode producer configured a system after a short trial period. During the primary smelting process, copper concentrate is typically processed into a higher purity matte stream and a waste slag stream containing impurities.

The key editable parameters that facilitated an easy installation were:

1) Detection alarms. The detection alarms allow the user to essentially switch the system from slag detection to metal detection mode, whilst changes the specific thresholds and delay time.

2) Tap temperature. The molten material temperatures are lower than in steel applications, so this field is now editable to a lower range to suit lower temperature tapping/pouring processes.

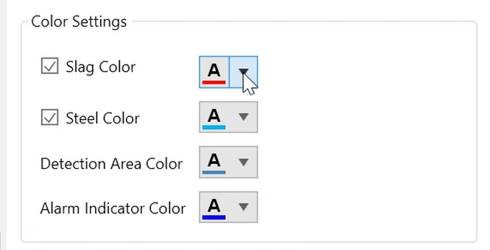

See the editable menu in the image below:

3) Slag/metal colours are now also easily customisable to suit the customer’s requirement

The resulting steam of slag/copper is shown below, with slag in red and copper in green. Using the system, the customer is able measure the real-time ratio of copper to slag and therefore recover copper into the production loop versus being wasted.

To learn more about our Slag Detection System, click here

To learn more about our Slag Detection System, click here