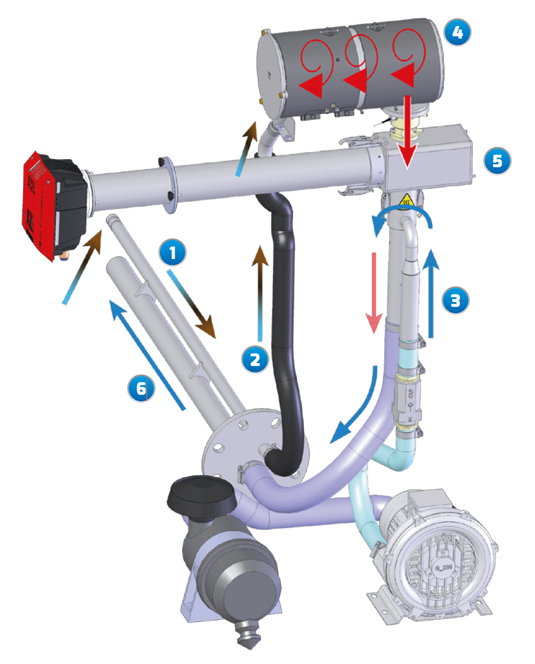

The 4650-PM EXN uses a heated extractive measurement system comprising a probe (1) and sample line (2). An eductor (3) draws the sample directly into a heated vaporizing chamber (4) to evaporate any condensed water droplets present in the stack. The resulting dry gas is measured using a stable and sensitive laser forward-scattering sensor (5). Flue gas is then returned to the stack by the same sampling port as the sample is taken (6).

The rugged and reliable design is ideal for all applications where condensed water may be present in stack gases, such as after a wet flue gas desulfurization system. The 4650-PM EXN is ideally suited for use in the

power generation, with wet FGD, incinerators and black liquor recovery boilers.

MEETS US EPA REGULATIONS

Meeting US-EPA Performance Specification 11 (PS-11), 4650-PM EXN is suited for users who need to comply with US EPA rules

COMPREHENSIVE CONTROL

4650-PM EXN is controlled via a simple control unit that includes a user interface for power, plus alarm contacts, 24V input, digital inputs, 4-20 mA output, RS232/485 and Data Bus. A multi-controller unit is also available, offering control of up to 4 devices.

EXTENSIVE MEASUREMENT RANGE

With the low angle forward-scatter measurement reducing sensitivity to particle size, 4650-PM gives a highly sensitive measurement ranging from 0.01 to 200 mg/m3, in temperatures up to 95 °C (203 °F).

4650-PM EXN is AMETEK Land’s particulate monitor for industrial combustion processes where condensed water droplets may be present.