Introduction to the Wedge Measurement Technique

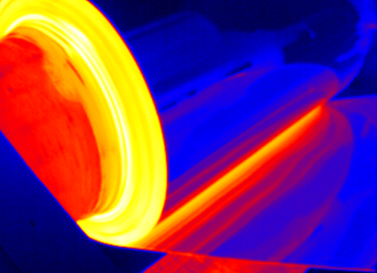

In the world of industrial temperature measurement, precision is paramount. Back in 1984, researchers at Nippon Kokan in Japan made a groundbreaking discovery: the cavity formed where a strip leaves a transition roll, commonly referred to as a wedge, exhibits an exceptionally high and stable emissivity.

This property remains consistent regardless of the strip material's actual emissivity value. This wedge effect, characterised by an emissivity close to 1, ensures accurate temperature measurements even in environments where the background temperature significantly exceeds the strip temperature.

The Wedge Effect in Thermal Imaging

The wedge, the space between the strip and the roll, creates a black body environment due to multiple internal reflections. Subsequent research by Land Infrared in 1986 confirmed that the typical wedge emissivity is an impressive 0.998, almost reaching the ideal emissivity of 1. This stability across a range of infrared wavelengths makes the wedge effect highly reliable for industrial applications.

Introducing the LWIR-640 for Wedge Temperature Monitoring

Leveraging this wedge effect,

LAND's LWIR-640 thermal imager has been designed to measure strip temperatures accurately in cold rolling and coiling processes.

Its advanced capabilities make it a vital tool for precise temperature monitoring in these applications. Here’s a closer look at the system design options available with the LWIR-640.

Option 1: LWIR-640 Autonomous Operation

The

LWIR-640 smart thermal imager offers a fully autonomous solution with an integrated webserver and multiple I/O options. This setup facilitates seamless integration into both new and existing process control systems. Users can access, control, and configure the camera using a standard web browser, eliminating the need for additional software.

Key Features:

•

Full access to camera and I/O settings via web browser

•

Continuous image monitoring for real-time temperature analysis

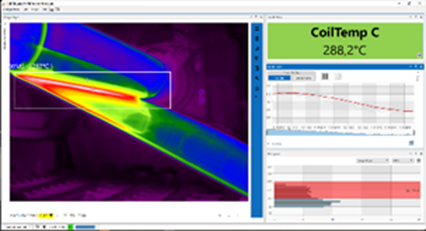

Option 2: Advanced IMAGEPro Process Control & Monitoring

The

IMAGEPro V2 software offers advanced thermal imaging capabilities for more sophisticated process control and monitoring. This software allows imager configuration, detailed display properties, and comprehensive temperature analysis, supporting multiple simultaneous imagers for extensive real-time analysis.

Key Features:

•

Real-time analysis with detailed control over thermal imaging measurements

•

Multiple interfacing options and advanced data-capturing capabilities

Conclusion

The

LWIR-640 thermal imager, with its ability to monitor the wedge effect, provides unparalleled accuracy in strip temperature measurement from -20-1000 °C (three ranges for choice).

Whether through autonomous operation or advanced process control with

IMAGEPro, the LWIR-640 offers solutions that cater to the demanding requirements of modern industrial environments.

Check out the Application Sheet

For more information and to explore how these systems can benefit your operations, reach out to LAND's expert sales team.