Accuracy matters, and the wrong choice of instrument can lead to costly errors.

That’s why understanding the differences between pyrometer types, and how they perform under real-world conditions is essential.

That’s why understanding the differences between pyrometer types, and how they perform under real-world conditions is essential.

At LAND, we’ve spent decades helping customers tackle temperature measurement challenges.

Our range of pyrometers are designed to meet the demands of complex industrial processes, from steel and aluminium production to galvanising lines and beyond.

Here’s what you need to know when selecting the right tool for the job.

Mono vs Ratio: What’s the Difference?

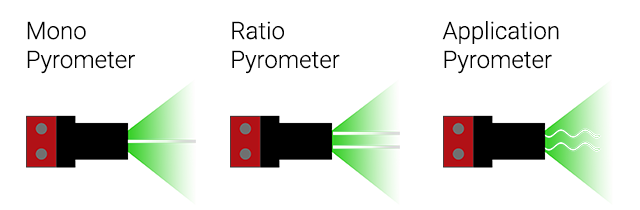

Mono (or monochromatic) pyrometers measure temperature using a single wavelength. They’re highly accurate when you know the emissivity of the surface and have a clear view of the product. But what happens when conditions aren’t perfect?

That’s where ratio pyrometers come in. Operating at two wavelengths, they compensate for dust, dirty windows, and even slight changes in emissivity, as long as both channels are affected proportionally. In other words, they keep working when the environment isn’t ideal.

Why Conditions Matter

Emissivity isn’t fixed. It can change with temperature, wavelength, or surface condition. Add dirt and dust into the mix, and the amount of radiation reaching the pyrometer drops.

That’s why choosing the right spectral range for your process is critical. Our SPOT+ range is built with this in mind, offering precision optics and proven electronics for repeatable, reliable temperature measurements.

Smart Features for Tough Environments

Smart Features for Tough Environments

The SPOT+ range doesn’t just measure temperature, it makes life easier. Integrated cameras, fibre optic options for tight spaces, and a built-in webserver mean setup and monitoring are straightforward.

For more demanding applications, the SPOT+ Ratio (R-Series) offers multiple operating modes, including Mono, Duo, Ratio, and Multi, giving you flexibility when you need it most.

Some processes need more than a standard pyrometer. That’s why we developed models like the SPOT+ GS and SPOT+ AL.

Some processes need more than a standard pyrometer. That’s why we developed models like the SPOT+ GS and SPOT+ AL.

The SPOT+ GS combines SPOT+ technology with advanced algorithms for continuous, accurate measurement of coated steel strip during galvanising and galvannealing.

The SPOT+ AL is tailored for aluminium processing, from extrusion and quenching to liquid metal tapping.

Accuracy You Can Trust

At

LAND, we design pyrometers to deliver dependable results in the most challenging conditions. Every instrument in our range reflects decades of experience and a commitment to precision.

Whether you need a mono, ratio, or application-specific solution, our technology is built to give you confidence in your measurements and keep your process running smoothly.

Click here to learn more about selecting the right pyrometer for your process.