PROCESS CONTROL BY NON-CONTACT TEMPERATURE MEASUREMENTS IN FORGING APPLICATIONS

PROCESS CONTROL BY NON-CONTACT TEMPERATURE MEASUREMENTS IN FORGING APPLICATIONS

There are two main forging processes used in industry: drop forging and press forging. Accurate temperature monitoring is vital in both scenarios. In this guide, we take a closer look at the processes, the challenges, and how non-contact temperature measurement solutions can improve production quality, efficiency and process control.

Download EN version here >

Download DE version here>

Download ESAR version here >

Download FR version here >

Download IT version here >

Download JA version here >

Download ZH version here >

SPOT+ M390 HIGH-TEMPERATURE MEASUREMENT IN REHEAT AND INDUSTRIAL FURNACES

The SPOT+ M390 , provides a continuous true temperature of the reheat furnace load and with it the possibility of big savings in operating costs.

Download EN version here >

THE ROLE OF TEMPERATURE MEASUREMENT IN SUSTAINABLE STEELMAKING

THE ROLE OF TEMPERATURE MEASUREMENT IN SUSTAINABLE STEELMAKING

The steel industry is responsible for approximately 7% of global manmade CO2 emissions. Finding a way to meet ongoing demands for the quantity and quality of steel required, while reducing and eventually eliminating carbon emissions, is a major challenge for everyone involved in steel production.

Temperature monitoring solutions can help in the transition to more sustainable methods of steelmaking, supporting decarbonisation in a number of ways. This technology is also suitable for use with a range of fuels, supporting the transition to hydrogen as a carbon-free fuel source.

Download EN version here >

IMPROVING SAFETY AND QUALITY IN CONTINUOUS CASTING MACHINE (CCM) LIQUID METAL APPLICATIONS

IMPROVING SAFETY AND QUALITY IN CONTINUOUS CASTING MACHINE (CCM) LIQUID METAL APPLICATIONS

Accurate temperature measurement of liquid metal during melting and pouring is important to ensure high-quality casting and efficient process operation. Traditional dip thermocouples present challenges for safety and measurement consistency, as well as incurring significant ongoing costs.

As the leading specialist in infrared non-contact temperature measurements for global industry, with extensive experience in liquid metal applications, LAND can supply a thermal imaging system to support process optimisation and safety at the point where the liquid metal stream leaves the tundish to moulds at the CCM billet caster.

Download EN version here >

TEMPERATURE MEASUREMENTS IN HEAT TREATMENT PROCESSES

Heat treatment is essential for the targeted influencing of important material and surface properties, such as softening a part, hardening its surface, or annealing stresses.

All of these processes involve precise temperature control in order to obtain the desired properties and guarantee their quality.

Download EN version here >

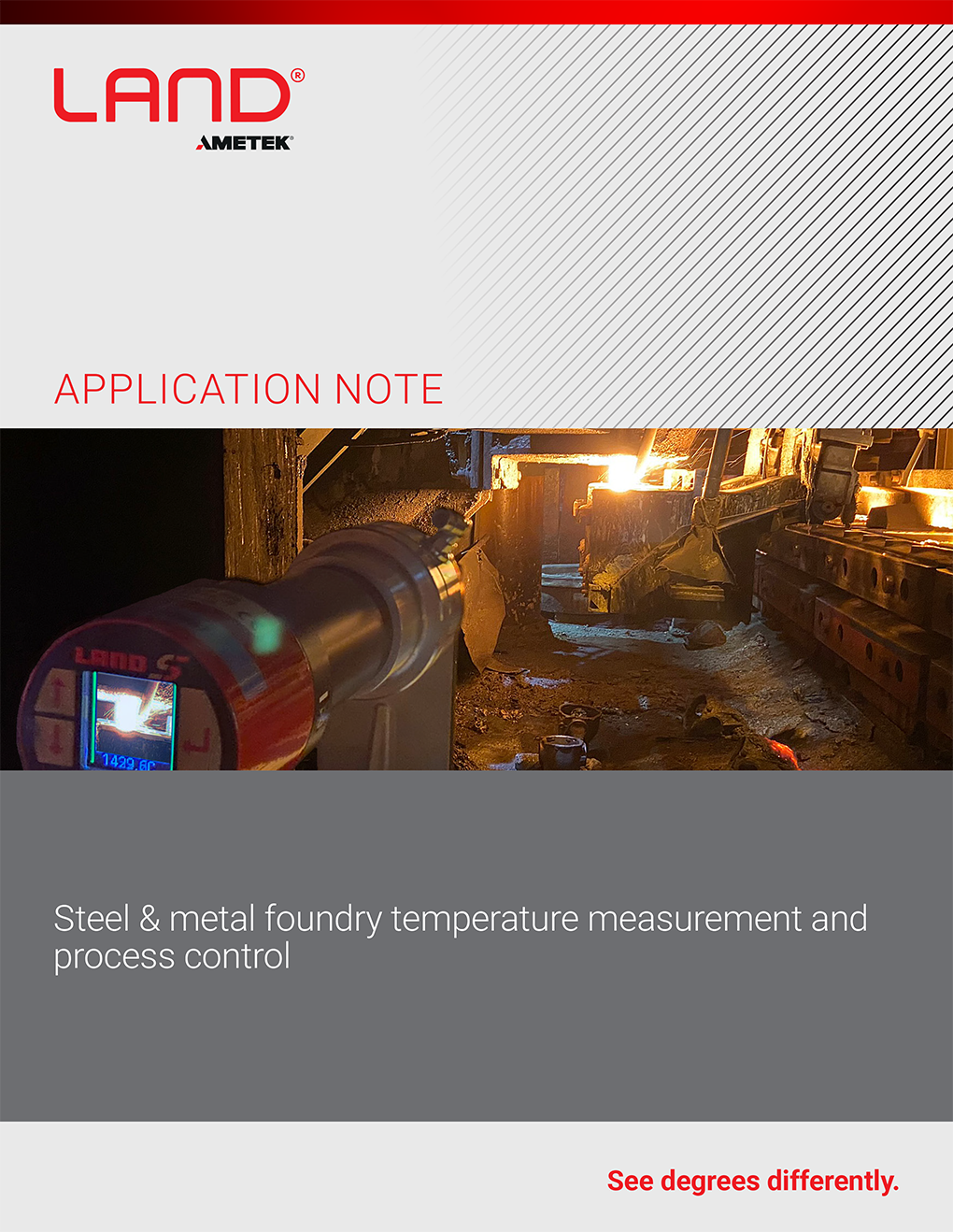

STEEL METAL FOUNDRY TEMPERATURE MEASUREMENT PROCESS CONTROL

Accurate temperature measurements is essential during the processing stages of liquid steel to ensure high product quality and optimise process efficiency.

Download EN version here >

PYROMETER TEMPERATURE MEASUREMENT IN CAL/CGL COATING LINES

PYROMETER TEMPERATURE MEASUREMENT IN CAL/CGL COATING LINES

Accurate temperature measurements are essential on annealing, galvanizing and coating lines, to ensure high product quality and optimise process efficiency.

Download EN version here >

STEEL CASTING AND HOT ROLLING

STEEL CASTING AND HOT ROLLING

Successful steel production requires accurate measurements across a wide range of temperatures,under a variety of different conditions. LAND is an experienced supplier of solutions to the steel industry, delivering dedicated solutions for key applications, and flexible instrumentation that can be customised for specific processes. Our products support process control, higher quality,lower emissions, and greater safety across the industry.

Download EN version here >

SPOT+ MONO, RATIO, OR APPLICATION PYROMETER SELECTION GUIDE

SPOT+ MONO, RATIO, OR APPLICATION PYROMETER SELECTION GUIDE

LAND offers a wide range of single-SPOT+ pyrometer types – Mono, Ratio, and Application – at a choice of several different and multiple wavelengths. The best choice for a particular application will depend on the application, the product to be measured and its surface conditions, and the process environment.

Download EN version here >

INFRARED PROCESS IMAGING SYSTEMS FOR VERTICAL CONTINUOUS ANNEALING LINES

INFRARED PROCESS IMAGING SYSTEMS FOR VERTICAL CONTINUOUS ANNEALING LINES

The continuous annealing line is used to modify the grain structure of steel through heat treatment, changing properties including hardness and strength. The process involves several stages, focused on controlled heating and cooling to produce steel with the required qualities. Accurate temperature monitoring and control in each zone is essential for process and quality control. To ensure the accurate, edge-to-edge temperature monitoring required, a solution has been devised that overcomes the challenges caused by surface reflections and strip emissivity.

Download ZH version here >

PROCESS OPTIMISATION IN METAL REHEAT FURNACES

PROCESS OPTIMISATION IN METAL REHEAT FURNACES

Reheat furnaces bring cold metal to the correct temperature for rolling, extruding or forging. For optimum quality, and to reduce wastage, the temperature should be uniform throughout the product, which requires accurate temperature monitoring.

Download EN version here >

COKE OVEN TEMPERATURE MEASUREMENT

COKE OVEN TEMPERATURE MEASUREMENT

High-quality metallurgical coke is a vital raw material for iron and steel production, affecting the furnace operation and standard of the hot metal. It is produced by heating coal in a coke oven in the absence of oxygen. Both the quality and quantity of coke, as well as the lifespan of the oven, depend upon uniform temperature levels, so these require close monitoring.

Download EN version here >

BLAST FURNACE, STOVE DOME AND HOT BLAST MAIN

BLAST FURNACE, STOVE DOME AND HOT BLAST MAIN

The quality and composition of iron produced in the blast furnace is directly related to the hearth temperature. This, in turn, is dependent on the temperature of the hot blast delivered from the blast furnace stoves. To maximise the efficiency of the stoves, they are operated at high temperatures, close to the safe working limit of the refractories. This makes it critical to carefully monitor the stove temperature.

Download EN version here >

COLD ROLLING MILL STRIP TEMPERATURE MEASUREMENTS

COLD ROLLING MILL STRIP TEMPERATURE MEASUREMENTS

Non-contact temperature measurement directly on the cold rolled metal surface can be challenging. There may be relatively low temperatures and variable emissivity involved, and the background environment may create reflections which disturb the measurement conditions.

Download EN version here >

MOLTEN METAL ESCAPES AND BREAKOUTS

MOLTEN METAL ESCAPES AND BREAKOUTS

The escape or breakout of molten metal is a highly important safety consideration in all metal manufacturing industries, particularly steelmaking. The extremely high temperatures involved make any breakout of molten metal extremely hazardous. However, if the metal mixes with water, it can instantly vaporise the water, causing a potentially explosive reaction.

Download EN version here >