The latest technology, including the Near Infrared Borescope (NIR-B) in-furnace thermal imaging system developed by LAND, has revolutionised the understanding of oxy-gas glass furnace operations in the glass industry.

T

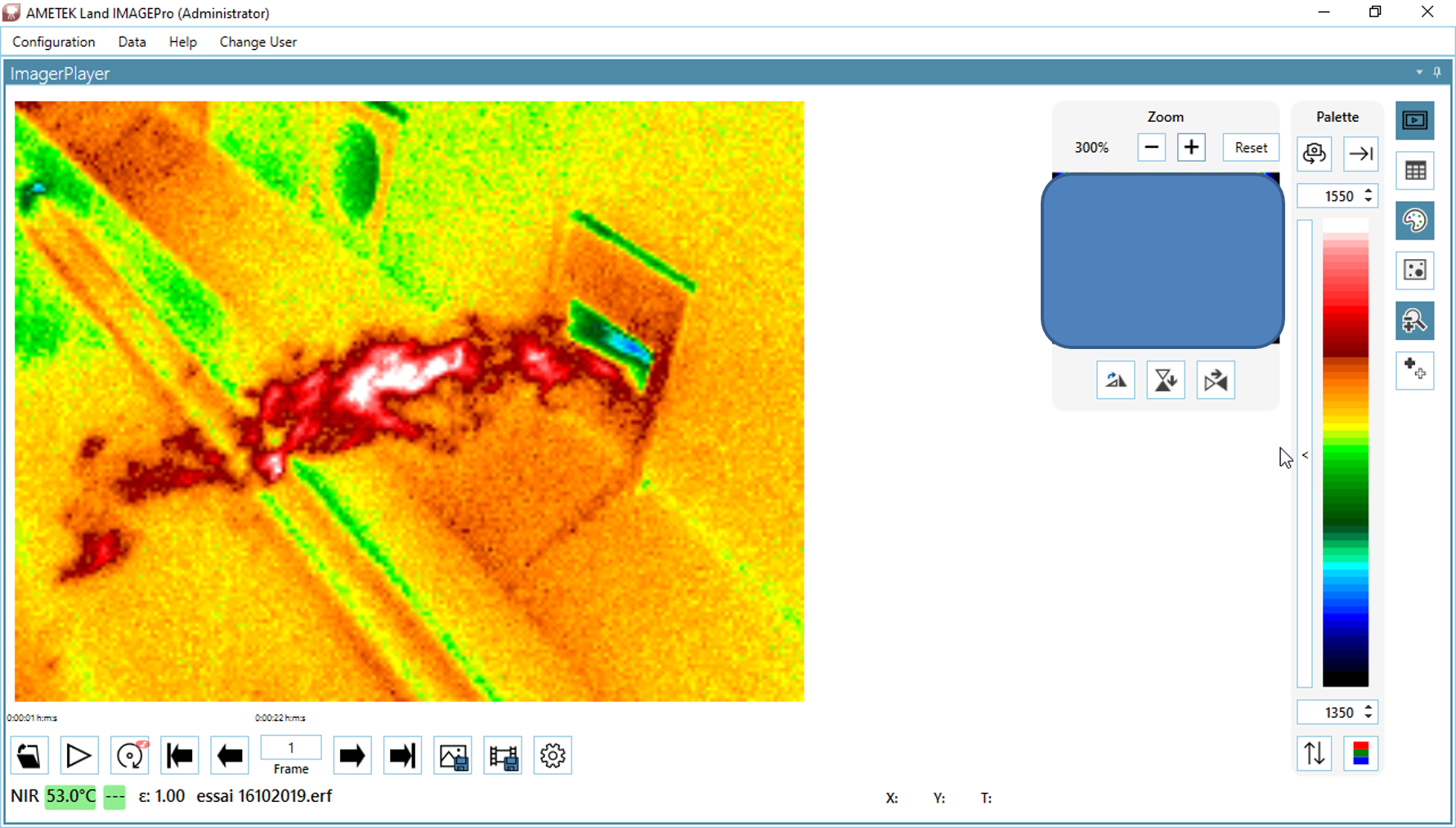

his advancement extends to end-fired or cross-fired regenerative furnaces, where glass producers leverage NIR-B data for Industry 4.0 compliance and furnace process optimization. The NIR-B delivers true-temperature radiometric images, providing continuous temperature values 24/7 to 3 million pixels with the new high-definition

NIR-B-2K Glass.

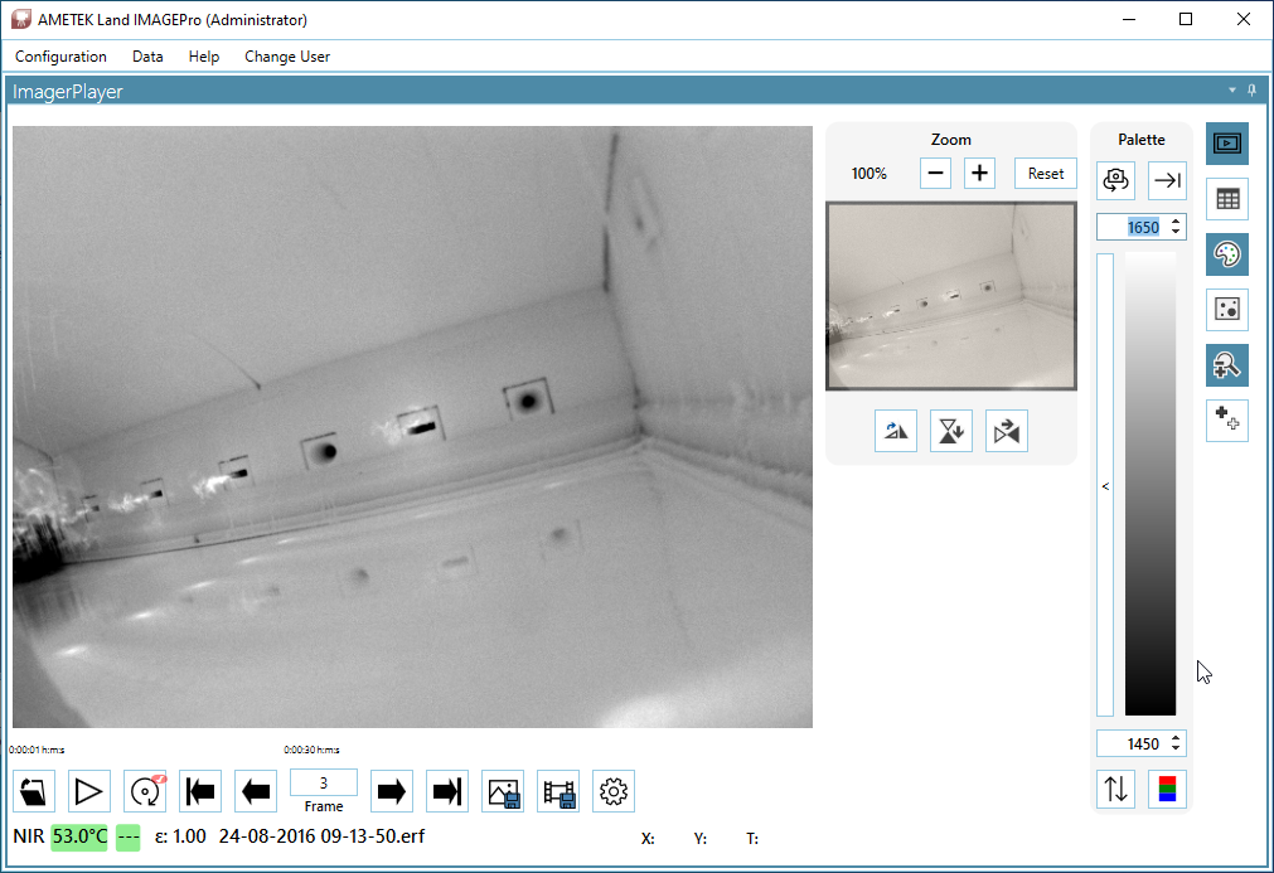

Maintaining consistent temperatures and thermal profiles in glass melt tanks is crucial for high-quality glass production and furnace longevity. Various temperature measurements within the furnace, including the crown, ports, and burner blocks, are essential. Additionally, visualizing cold spots in refractories helps identify air leaks or structural issues.

The new

IMAGEPro software allows for temperature measurement along the melt line, batch coverage, and batch transit time, facilitating recording and comparison. The NIR-B offers benefits such as thermocouple verification, thermal profiling, air ingress detection, combustion optimization for energy efficiency, and emission control.

Thermocouple verification for oxy-gas melter ensures accurate temperature data, while the

NIR-B aids in monitoring hot spots and burner conditions to prevent potential damage. The technology's ability to continuously monitor furnace thermal profiles and confirm hot spot locations aligns with Industry 4.0 requirements.

Operators can draw profile lines to obtain continuous thermal profiles, contrasting with manual methods or thermocouples. Infrared temperature measurement aids in highlighting best practices within glass melt tanks, enabling necessary repairs and flame optimization.

The NIR-B's massive data capture capability necessitates real-time analysis and long-term trend monitoring. Snapshot images taken daily enable comparison and identification of short-term problems and long-term changes, supporting preventive maintenance scheduling and quick reactions.

Isotherms provided by the NIR-B highlight cold and hot locations, aiding in asset protection against overheating and condensation zones. Burner block inspection and furnace heat-up monitoring are enhanced with the NIR-B's zoom function and transportable model, enabling comprehensive thermal surveys.

In conclusion, the NIR-B Imaging Borescope offers a comprehensive solution for optimizing glass furnace operations, ensuring precise temperature monitoring, proactive maintenance, and process optimisation in line with Industry 4.0 standards.

Click here to learn more about the NIR-B-2K Glass