In this blog, we will explain how our line scanning LSP-HD system could reinforce the quality of glass ribbon products during the annealing process into the lehr.

The cooling rate and homogeneous thermal distribution across the width and length of the glass ribbon within the annealing lehr and forced air cooling zones are essential to float glass quality.

Frequent, accurate measurements of the temperature profile are necessary to reduce stresses in the glass and to optimise the cooling rate over the entire process length. With the development of the

LSP-HD linescanner,

AMETEK Land provides a non-contact infrared solution for accurate temperature-cross profile measurements that optimise the annealing process and minimise thermal variations across the width of the glass, making the production of thinner or thicker glasses possible.

The LSP-HD solution can cover the different locations of the lehr. The hottest locations from A to C can be covered by the LSP-HD float line mounting with the LSP-HD 5FL, and the coldest from location D to E with the LSP-HD 60 or LSP-HD 5.

For the typical location F, where the temperature of the glass ribbon could be

below 100 °C, the LSPHD 60 will be used; this is the typical application described in this document.

The lehr measurement challenge:

The lehr is a long, temperature-controlled kiln divided in different locations from A to F Glass passes through the lehr to ensure a consistent temperature gradient as it cools. If the glass was allowed to cool in ambient air, the surface would lose heat more quickly than the interior of the glass, creating stresses which are likely to crack or break the glass.

Float glass manufacturer

Saint-Gobain Glass Germany GmbH challenged

AMETEK Land to find a solution for the measurement of temperature distribution in Location F across the glass width in the forced air-cooling zones downstream of the annealing lehr.

The company required the solution to have a high measurement accuracy, within less than 2 °C and high reliability over time. It also had to avoid thermometer drift and provide simple evaluation through the process control system.

A solution was proposed to monitor five zones across the width of the ribbon to monitor the effects of air flow on the glass temperature. Initially, the customer favoured a five-point array of infrared thermometers in series. The solution proposed was based on the RT80A, a non-contact infrared thermometer. This was a cost-effective solution that could be easily installed.

The RT80A is derived from the same thermometer series, which is already used on the tin bath and provides trusted, safe temperature monitoring data.

The drawback of this method, however, is that it relies on spot measurements at the five locations, resulting in an averaged temperature indication over the respective field of view of a spot thermometer, and thus the local resolution of the actual temperature profile across the width is not very meaningful.

In addition, it relies on five different detectors, each with their own drifts and deviations, increasing the systematic error in the measurement

Accurate temperature-cross-profile measurements – utilising Landscan systems or single-point thermometers downstream of the lehr in the air-cooling zones and at the cutting section – are vital when producing thin or thick glass to maintain stable, continuous cooling, which avoids glass breakage and maintains quality.

Measurement at the annealing lehr exit is used to highlight any breakages of the glass. Acting as a single “presence detector”, a thermometer or linescanner placed at this point aids the complete automation of the process.

Lehr – Hot Sections with LSP-HD 5FL and FLT5A:

After the solidified glass leaves the tin bath, it moves to the lehr, where it is cooled gradually to remove internal stresses. The rate of cooling is important to ensure the glass does not break at the cutting stage, so frequent, precise temperature measurements are critical to this application.

The

LSP-HD 5FL is a high-speed 5 µm linescanner, when integrated as part of a multi-head linescanning system, provides unprecedented levels of information and control of glass temperature in the lehr.

Lehr – Cold sections with LSP-HD 60 and RT80:

Float glass, also known as flat glass, is produced by allowing the glass ribbon to solidify on a layer of higher-density liquid to create a flat sheet. Using this method, glass sheets can be manufactured with highly uniform thicknesses and very flat surfaces.

The float glass process is used to create clear, tinted or coated glass which can be used for a wide variety of applications, including architectural and automotive glass. The quality of the end product is highly dependent on precision temperature measurements and uniformity of cooling.

AMETEK Land provides a comprehensive range of solutions for measurements throughout float glass production, including portable thermometers and real-time monitoring of the melt tank interior.

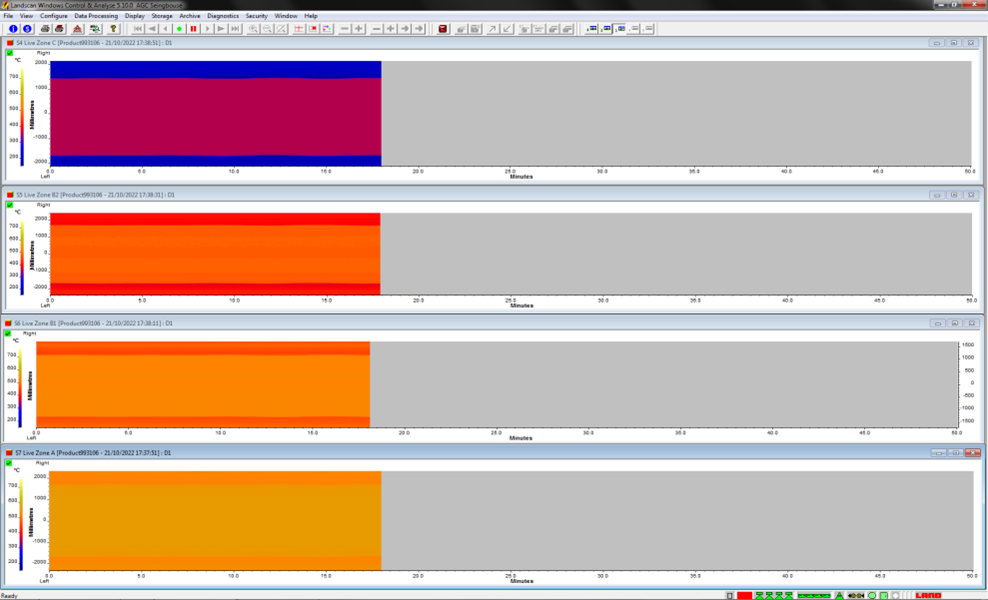

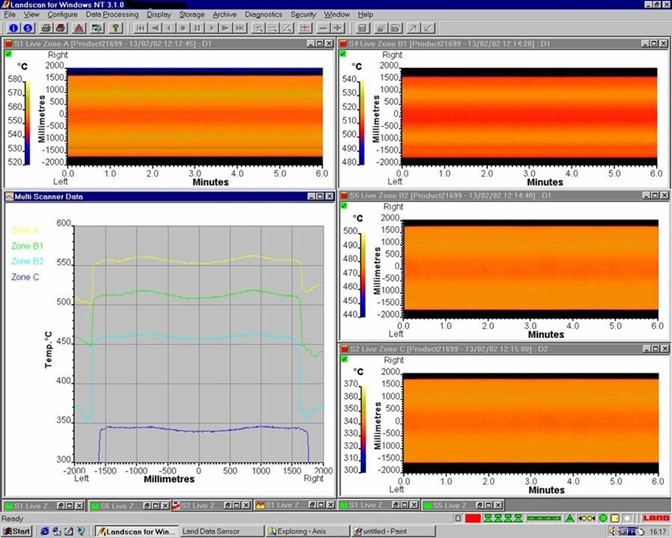

Software technical analysis and visualisation of the measurement data via the WCA software:

The

LSP-HD linescanner range supports easy, plug-and-play compatibility with

AMETEK Land’s Landscan Windows Control and Analyse (WCA) software package.

The Landscan WCA suite provides detailed control and analysis for up to eight linescanners, enabling the viewing and analysing of multiple live and historical temperature data streams.

Offering flexible, scalable capabilities, the Landscan WCA delivers advanced, high-resolution thermal imaging data in real time. Tagging and linking multiple live data streams enables the easy creation of production process databases. A PC-based platform, Landscan WCA provides access to temperature measurements and processed data through a range of standard industrial interfaces, including cross-platform TCP/IP protocol, OPC, analogue signals and alarm outputs.

The clear visualisation of the flat glass temperature profile provided by the Landscan WCA software using data from the LSP-HD was key to proving the effectiveness of the system behind the lehr measurements.

In conclusion, the LSP-HD 60 and LSP-HD 5 FL line scanning systems support the following features and benefits:

Features:

High-resolution optical system

Industry-leading 150 Hz scan speed

Designed to operate in harsh industrial environments

Plug-and-play installation via a single Ethernet cable

Range of data output formats

Benefits:

Full-width measurement identifies smallest temperature variations

Process modelling improves process control

Accurate thermal records for product quality data

Real-time thermal displays

Easy connection to process control system

Four heads on location Zone A, B1, B2 and C with Maps

Four Heads location Zone A, B1, B2 and C with Maps and 2D profiles