The NIR-B-2K-Glass camera could be integrated into the DCS control of the furnace and be connected to the existing PLC to collect and exchange data to a SCADA.

The native OPC UA server of

IMAGEPro V2 can be connected to any container glass plant PLCs, providing accurate temperature profiling and continuous furnace monitoring for any set-up based on data exchange for SCADA.

SCADA stands for Supervisory Control and Data Acquisition. The term refers to a system that combines software and hardware, enabling industrial organisations and factories to control processes and equipment. The system receives process-related data from devices and equipment across the operation, whether spread out in different locations or within one facility. SCADA operators and supervisors then use this data to monitor processes; maintain and improve efficiencies; improve quality and profitability; reduce waste; identify problems and emergencies, and deal with them quickly and efficiently.

The SCADA software receives the data collected from machinery, equipment and devices and processes it. The data is then displayed on screens and dashboards, often in animated graphs, diagrams, and images, so that operators know in real time what is happening on the floor or in the field. The operator can analyse this data to determine whether operations are running optimally or whether they need adjustment or urgent intervention. For example, operators can use the SCADA system to change rates and settings, recalibrate equipment or shut down a process altogether if necessary.

A native OPC UA (or an optional single gateway device) connects your

NIR-B-2K- Glass camera to any PLC set-up, including Profinet and Profibus protocol; this means all data coming from the NIR-B-2K can be exchanged to SCADA for optimisation of energy and emissions of any glass furnaces.

The

IMAGEPro Version 2 Glass is a PC-based software combined with the NIR-B-2K thermal imagers with the ability to communicate natively with modbus, TCP and OPC UA; this is already covering a large part of the industrial protocols in the glass industry.

The

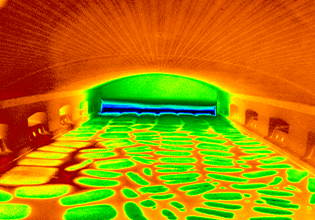

NIR-B-2K Borescope, whilst providing continuous temperature monitoring of refractories, also provides a thermal crystal-clear visual image inside the glass tank and visualisation of flames and or flame heat distribution. This allows the system to monitor and alarm if there is flame impingement which is very important on Oxy-fuelled furnaces. The

AMETEK Land Image Processing Software provides an integration function which reveals true flame intensely, offering an insight into the efficiency of combustion, flame length optimisation and NOx generation.

Additionally, the new IMAGEPro Software V2 with glass extension provides batch coverage functions, including:

•

Batch line monitoring and batch carryover.

•

Batch transit time and temperature of the blanket.

•

Batch velocity vectors using time-lapse.

•

Batch charger optimisation and troubleshooting.

AMETEK Land’s

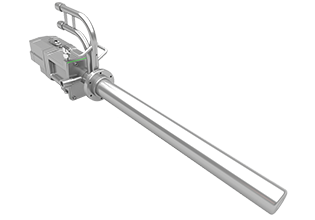

NIR-B-2K Borescope delivers this new approach by combining the

Cyclops C100L. The NIR-B-2K is a short wavelength, radiometric infrared borescope imaging camera that produces high-definition (3 million pixels) thermal images and enables accurate temperature measurement from any point in the image. The camera measures temperatures from 600° C to 1800° C (1112° F to 3272° F). There are many advantages to thermal vs. visual imaging and point temperature measurements.

Using a permanently installed thermal-imaging camera that actively records all necessary points, it is possible to have additional virtual point thermocouples but, in addition, 100 regions of interest (ROI), including profile lines.

If an alarm of temperatures is triggered, then in addition to output to the DCS, a snapshot of the condition is taken, providing an opportunity to review any incident. Most measurements should be taken on the day when the best operation was experienced so we have a point of reference when things are optimal.

The move to Oxy-fuels and fuel conversion could be a step associated with thermal imaging on furnace operations, whatever the technology. Or it could be simply to optimise the combustion at first, and even if the NIR-B-2K thermal camera is NOT the overall solution, this is a tool to consider when moving towards decarbonisation.

Operators can check the visual information coming from the

NIR-B-2K-Glass interface but can also use different information and connect the thermal imager to any PLC using a data acquisition and protocol conversion platform for DCS or SCADA control. This way, any data of temperatures coming from a zone named ROIs can be exchanged with the furnace’s PLC.

The zones could be any ROIs on the refractories but could be also in the melting zone thanks to the greed IPV2 glass software is creating. Any cells of this greed could be a percent of the batch, temperature or alarms providing a real position of the batch location.

The optional gateway Red Lion Gateway DA30D data station is opening communication protocols to Rockwell (ethernet-IP), and Siemens ( Profibus and Profinet).

Working in partnership with your engineering and IT teams, we can ensure that the benefits of our NIR-B-2K-Glass thermal imaging camera can be applied to your container glass plant.

Seamless communication between the thermal imager and PLC is delivered by using our

IMAGEPro Version 2 software, which has up to three built-in serial ports and a 10/100Base-T(X) Ethernet port with the additional gateway DA30. Up to 10 different Ethernet-based protocols are supported for ease of communication, and additional options such as CAN, DeviceNet, Profinet, Ethernet/IP and Profibus are included.

Streamlined data transfer to management and enterprise systems.

An embedded OPC UA server and client eliminates the need to connect the NIR-B-2K-Glass to additional intermediate server hardware. Users can enable the OPC UA server feature with a simple Yes/No selection and select any data tag to make it available to OPC UA clients. Dead bands can also be added to any tag to reduce communications overhead.

Easy integration into your IIoT strategy

The intuitive point-and-click user interface simplifies communication between the thermal imager and otherwise incompatible communications standards, easily converting between serial, Ethernet, and Fieldbus devices. Using the DA30D and easy-to-follow cloud connector services editor, on-site or cloud-based connectivity can be added directly to our equipment.

Automation and management of remote assets

The data station excels at keeping personnel informed of machine and process performance. With its built-in web server, remote personnel can monitor as well as control the NIR-B-2K-Glass and other equipment from most networked devices. This web server supports HTTPS operation with the provision of certificates, responsive design with a full-screen option ideal for tablet or mobile display, and an HTTP redirect. The data station can also alert personnel about existing or potential issues detected by the thermal imager, so problems can be addressed quickly and downtime minimised.

Harness the value of thermal image data

With its built-in data, event and security logger,

IMAGEPro V2 offers a powerful means for recording continuous data from the thermal imager. Data can be acquired from the thermal imager and compiled into a single CSV-formatted file, where it can be stored, displayed, emailed, or automatically synchronised with an FTP or Microsoft SQL server thanks to the optional gateway.

How It Works:

Generic Network architecture IPV2 using optional gateway DA 30

After defining the regions of interest (ROIs) with the AMETEK Land IMAGEPro software and setting up communication between the NIR-B-2K-Glass camera and the IMAGEPro server PC that will receive this data, the native OPC UA server (or Red Lion DA30D Gateway for profibus , profinet and Rockwell Ethernet IP) will be responsible for sending the data from the IMAGEPro PC server to any PLCs for data exchange on the IP network.

The typical network would therefore be as follows:

Following the configuration of the import file for generating scripts with the DA30D’s Crimson 3.1 software, the communication between the IMAGEPro PC server on the plant network could be addressed to any PLC standards on the automation market, including commonly used brands such as Schneider, Rockwell, Eurotherm, and Siemens.

Importation of data tags with optional DA30

The application creates scripts to exchange data tags. Data received from the PC server is stored in data labels in the DA30D Gateway. Each change of a data tag, and the value of this tag, is sent to the PLC corresponding to data from the thermal imaging camera.

It is initially necessary to define these data tags in IMAGEPro V2 (and through the DA30D Gateway with all the Excel scripts provided when the gateway is used and connected to the IMAGEPro server).

Summary:

AMETEK Land provides a full user guide for connecting your NIR-B-2K-Glass to a PLC via the existing native OPC UA server.

This includes connections, software configurations, and defining the regions of interest. It also covers importing the data exchange table for the camera and PLC communications for a range of protocols.

To share data from the

IMAGEPro V2 software with a SCADA system for glass furnace optimisation, you would typically need to establish a communication link between the two systems. Here are some steps that might be involved:

Connect the IMAGEPro V2 system: Ensure that the IMAGEPro V2 system is connected to the same network infrastructure as the SCADA system or has a dedicated connection for data sharing.

Data acquisition and configuration: Configure the IMAGEPro V2 software to capture relevant data from the glass furnace, such as thermal images, temperature measurements, or other parameters. Set up the software to collect this data periodically or based on specific triggers (hot spot or Batch coverage) .

Data transmission: Determine the method of data transmission from the IMAGEPro V2 system to the SCADA system. This could involve using standard protocols like OPC or Modbus, or proprietary interfaces provided by both systems.

SCADA system configuration: Configure the SCADA system to receive and process the data transmitted from the Image Pro V2. This may involve setting up data points, visualisations, alarms, and data logging for the received data.

Data integration and visualisation: Once the data is successfully transmitted and received by the SCADA system, integrate it into the overall visualisation and monitoring interface. This allows operators to view the temperature data, thermal images and hot spot locations, and other relevant information in real time alongside other process parameters.

Our team of experts aim to work with your IT to develop the best route to implement the installation of the thermal imager into your PLC. Full collaboration with your engineers and IT staff allows a seamless configuration that ensures your glass plant achieves all the benefits of a connected NIR-B-2K-Glass thermal imager, whatever your PLC configuration may be.

Click here to learn more about the NIR-B-2K Borescope