In the intricate world of steelmaking, even the tiniest details can make a colossal difference. One such detail that might not grab the headlines but profoundly impacts safety and efficiency is the Ladle Freeboard.

Understanding Ladle Freeboard:

Understanding Ladle Freeboard:

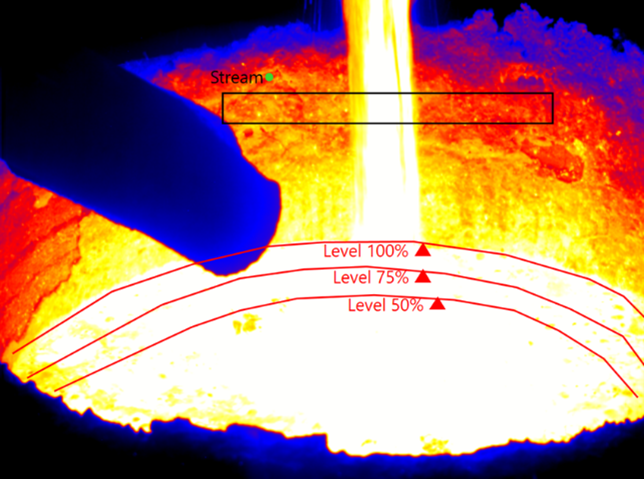

The Ladle Freeboard is the unsung hero nestled between the upper rim of a ladle and the molten metal surface it cradles. This seemingly minor gap holds the key to a safe and streamlined steelmaking process. Why? Because it dictates the amount of molten metal to be transferred, ensuring that the ladle isn't underfilled, leading to production hiccups, or overfilled, risking spills and mishaps.

The Challenge of Measurement:

Visualizing this critical gap isn't as simple as peering into the pot on the stove. The intense heat, smoke, and fumes engulfing the ladle create a veil of obscurity. So, how can one possibly measure it? Here comes technology to the rescue.

From Human Eye to Radar: A Spectrum of Solutions:

Traditionally, skilled human operators gauged freeboard levels. But even the most seasoned eye can be fooled by smoke and shifting light conditions, not to mention the prolonged exposure's toll on eyesight.

Radar technology brought innovation to the table. Emitting microwaves, it gauges the distance to the liquid surface. However, its efficacy falters in extreme heat, and reflective surfaces like molten metal can muddy its accuracy.

Thermal Imaging: The Futuristic Solution:

Enter thermal imaging, an advanced, non-contact technique that transcends the limitations of the human eye and radar. Imagine looking at the world through heat signatures. With thermal cameras like AMETEK Land's

MWIR-640 390, measuring

ladle freeboard becomes more than just numbers – it's a visual journey through temperature distributions.

Why Thermal Imaging Reigns Supreme:

Contactless and Safe: No contamination risks, and no need to wait for smoke to clear. The process remains seamless.

Real-time Insights: A real-time window into the ladle's thermal landscape. Adjustments can be made swiftly, minimizing disruptions.

Withstands Extreme Heat: Designed to thrive in the scorching temperatures of the steelmaking environment, ensuring consistent and reliable measurements.

Comprehensive Perspective: Capture the whole picture with a wide field of view. Detect irregularities, identify hotspots, and optimize management.

Interference-Free: Unlike radar, thermal imaging sidesteps interference issues caused by reflections and electromagnetic noise.

The AMETEK Land Advantage:

AMETEK Land's

MWIR-640 390 thermal imager isn't just another gadget; it's a game-changer. Equipped with advanced spectral filtering, it pierces through smoke and particles to deliver clear images. With temperature ranges spanning from melting to final processing, it covers the entire spectrum of steelmaking. Its integration with automation systems ushers in a new era of streamlined data acquisition and operational efficiency.

In the realm of steelmaking, where precision reigns supreme, the Ladle Freeboard emerges as a decisive factor. Whether through the seasoned eye, radar pulses, or the futuristic gaze of thermal imaging, measuring this unsung gap becomes a cornerstone of safety and efficiency. With

AMETEK Land's cutting-edge technology, the future of steel production looks clearer, safer, and more efficient than ever before.