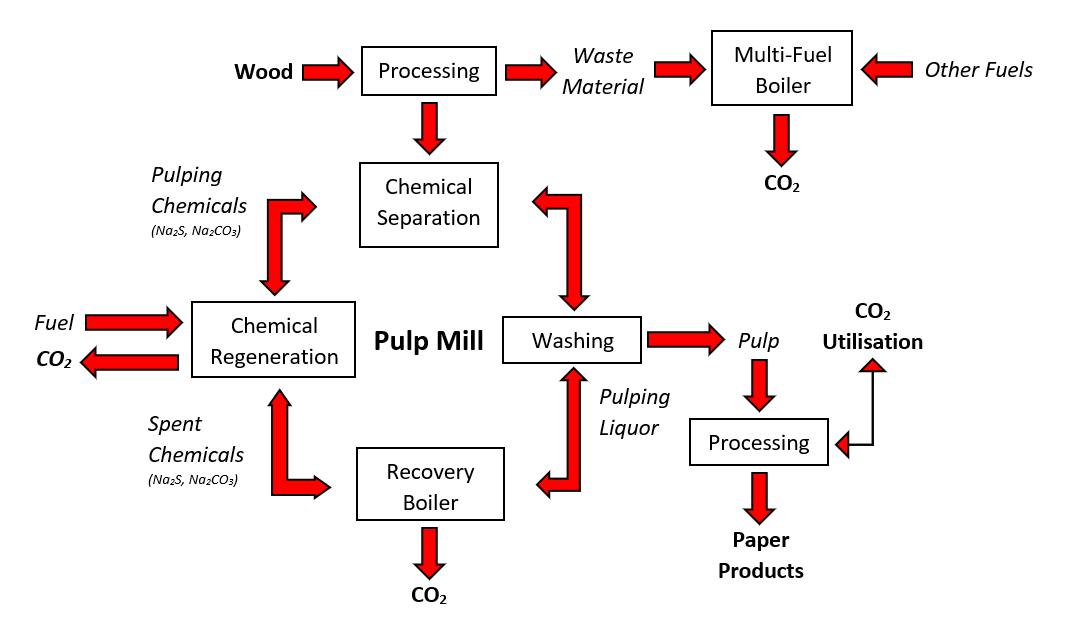

The kraft process is widely used to convert wood into pulp for papermaking. The process is very efficient because most of the chemicals used to process the wood can be recycled. In the process, the lignin and hemicellulose are separated from the desired cellulose fibres.

Once the cellulose fibres have been separated, the remaining solution is known as black liquor. This has a high heat content because of the dissolved lignin and hemicellulose. The black liquor is concentrated by evaporation and sprayed into the recovery boiler where it burns to produce heat. The non-combustible minerals are deposited as a semi-liquid smelt in the bottom of the boiler.

Because of the chemical recovery function, there are some combustion control issues in a black liquor recovery boiler that do not apply to a conventionally-fueled boiler. A key issue is the size of the droplets formed as the black liquor is sprayed into the boiler and the resulting rate of combustion. The droplet size needs to be large enough that it reaches the smelt bed while it is still burning, but not so large that it still contains water when it reaches the bed. Very small droplets will not reach the bed at all, as they will be carried out of the boiler by the flue gas flow.

A borescope thermal imager operating in the md-wave infrared region can visualize the spray nozzle and the fuel flow and the smelt bed with limited interference from the burning droplets. The AMETEK Land

MWIR-Borescope-640 is ideal for such applications, with the proviso that it cannot use the standard cooling jacket for safety reasons. Water cooling is not permitted because even a small leak of water onto the hot smelt bed can cause a severe explosion. A special air-cooled jacket must be used for this application.

The image below was recorded using an MWIR-B. it shows the vertical boiler tubes in the central portion of the mage and the spray of black liquor in blue and green towards the bottom. The ability to visualize the boiler conditions, including the fuel distribution, allows the operator to optimize the fuel flow for maximum efficiency.