Hybrid furnaces, which combine combustion (particularly oxy-gas) with electric boosting, are at the heart of industrial decarbonisation strategies in energy intensive sectors such as glass, steel, and non-ferrous metallurgy.

While oxy-gas combustion improves fuel efficiency and reduces emissions, achieving accurate in-situ thermal monitoring still remains a key challenge.

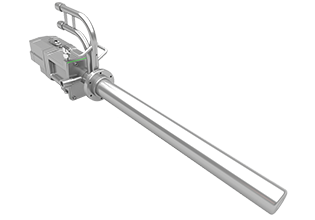

LAND’s

NIR-b-2K infrared borescope camera offers continuous, non-contact, temperature measurements, enabling better process control even in harsh operating environments.

This blog explores the principles and industrial applications of oxy-gas combustion and NIR-b-2K technology, and how their integration in hybrid furnaces supports energy efficiency, emissions reduction, and global decarbonisation goals.

Introduction

High-temperature furnaces are essential to global manufacturing, but they are also among the most carbon-intensive industrial assets. Transitioning to low-carbon furnace technologies is critical to meeting climate targets.

Hybrid furnaces, which combine electric boosting with oxy-gas combustion, offer operational flexibility, especially when powered by renewable electricity. By replacing air with oxygen, oxy-gas combustion improves fuel efficiency and reduces both NO

x and CO

2 emissions. These technologies help reduce fossil fuel consumption while maintaining high product quality.

Consistent and accurate thermal monitoring is essential to balance energy inputs, prevent refractory damage, and ensure uniform heating. The LAND NIR-b-2K camera provides continuous, real-time temperature data from inside the furnace, helping operators meet these demands.

Oxy-Gas Furnace Technology

Key Principles

Oxy-gas combustion replaces nitrogen-rich air with pure oxygen, reducing NOₓ formation compared to regenerative furnaces.

This lowers flue-gas volumes by up to 60%, increases flame temperatures, and improves radiative heat transfer.

Benefits include fuel savings of 15–40%, NO

x reductions of up to 80%, and lower CO

2 emissions per tonne of daily production.

Industrial Applications

Glass manufacturing: Improved melting efficiency, fewer defects, and reduced emissions.

Steel and non-ferrous metallurgy: Retrofitted oxy-fuel burners deliver higher productivity and energy savings.

Hybrid systems: Enable flexible switching between combustion and electric inputs, with some projects achieving up to 50% CO

2 reduction.

LAND’s NIR-b-2K Camera Technology

The LAND

NIR-b-2K camera uses near-infrared imaging (centered at 1 µm) to provide accurate non-contact temperature measurements. Key features include:

•

Real-time imaging up to 1800 °C

•

Wide-angle field of view (95° x 71°) via a borescope inserted into furnace walls, placement options include front or back wall

•

Reliable operation in harsh environments (dust, flames, ambient temperatures up to 80 °C)

•

Digital outputs (OPC UA, Modbus, TCP/IP) for integration with control systems and predictive software

This makes the

NIR-b-2K ideal for hybrid and oxy-gas furnaces, where fluctuating thermal loads require precise monitoring. Isotherm modes help identify hot and cold spots.

Integration in Hybrid Furnace Operations

Energy Efficiency and Control

The

NIR-b-2K camera helps optimise the balance between combustion and electric inputs. Oxy-gas burners can be fine-tuned for better oxygen-to-fuel ratios.

Quality Assurance

In glass and steel production, the camera detects uneven heating zones, helping prevent defects and maintain consistency. The

ImagePro V2 Glass software includes an AI-driven neural network that calculates batch coverage and deviation from theoretical batch lines. This helps operators achieve the correct thermal profile between furnace walls.

Together, these tools allow operators and batch-and-furnace managers to maintain daily balance, ensuring stable production and optimal pull rates.

Emissions Reduction

Accurate monitoring helps reduce excess oxygen, lower fuel use, and minimise CO

2 and NO

x emissions.

Extending Furnace Life

Thermal imaging can detect refractory wear, hot or cold spots, and overheating early, supporting predictive maintenance and extending furnace lifespan.

Supporting Decarbonisation

Hybrid Furnace Benefits

•

Enables electrification of melting zones or forehearths, cutting CO

2 emissions when powered by renewables

•

Offers flexibility to maximise renewable input based on grid availability and carbon pricing

•

Proven CO₂ reductions of up to 50% compared to conventional air-fuel furnaces

Oxy-Gas Advantages

•

Improves combustion efficiency, reducing fuel demand and emissions

•

Cuts NOₓ formation and flue-gas volumes, making CO

2 capture easier

•

Helps meet environmental regulations through significant NO

x reductions

Optimised Hybrid-Oxy Approaches

•

Hybrid furnaces with oxy-fuel burners balance combustion and electricity for maximum decarbonization

•

Oxy-fuel flue gases (mainly CO

2 and H2O) simplify integration with carbon capture systems

•

These technologies offer a clear pathway to net-zero for high-consumption industries

Case Study: Oxy-Gas Furnace in Fibre Glass Production

In the fiber glass reinforcement sector, oxy-gas furnaces are widely used, either with CGM top burners or traditional side burners.

A leading fiber glass producer adopted the

NIR-b-2K camera on selected furnaces. Initially, the furnace was commissioned using thermocouples and

Cyclops handheld pyrometers for optical profiling. These methods suggested the furnace was balanced.

However, once the NIR-b-2K was installed, it revealed a 20 °C temperature imbalance between the left-hand side (LHS) and right-hand side (RHS). Further analysis showed the RHS burners were not optimized, an issue missed by traditional measurement methods.

Fig. 1

Fig. 1: NIR-b-2K thermal image of a 150 tpd oxy-gas furnace producing fibreglass, showing bubbling line and burner layout

Fig. 2:

Fig. 2: Orange palette visualisation confirms RHS is hotter than LHS due to unoptimised burners

Fig. 3:

Fig. 3: Optimised RHS burners demonstrate the camera’s value in fine-tuning burner power

Fig. 4:

Fig. 4: ImagePro V2 Glass software shows AI-based top view of melting zone, batch line deviation, and wall temperature correlation

Conclusion

Combining oxy-gas combustion, hybrid furnace design, and LAND NIR-b-2K thermal imaging creates a powerful solution for improving efficiency, product quality, emissions control, and sustainability.

These technologies support industrial decarbonisation while maintaining productivity and reliability.

Their integration marks a major step forward in the journey toward net-zero for high-temperature process industries.