Furnace monitoring and diagnosis are crucial for hot-end industrial processes such as glass making, steel production, and the petrochemical industry.

While visual cameras have traditionally been used for observation, near-infrared (NIR) borescopes, particularly high-definition (HD) systems like the LAND

NIR-b-2K with its 3-million-pixel resolution, have enabled a more comprehensive and data-driven approach.

This blog explores the functional and operational benefits of NIR-borescopes compared to traditional visual cameras, with a focus on the unique capabilities and performance of

LAND’s NIR-b-2K HD.

How NIR-borescopes Work

High-temperature furnaces operate in harsh and often hostile environments, challenging the performance of conventional monitoring systems. Visual cameras, while offering direct inspection, are not quantitative and fail to provide insights into the thermal behaviour of furnace structures, which can restrict and limit furnace operations.

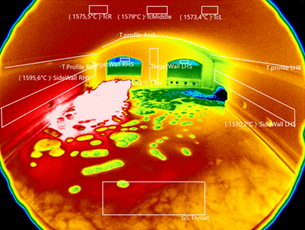

NIR-borescopes capture thermal images with higher resolution in the near-infrared spectrum than colour cameras, offering improved digital imaging and radiometric detail. Optical borescopes like the NIR-b-2K HD provide high-resolution thermal imaging, enabling operators to optimise combustion and receive real-time, radiometric temperature readings. This thermal visibility allows for broader diagnostics, continuous monitoring, and enhanced process control.

Infrared Thermal Imaging and Temperature Measurement

The NIR-b-2K HD is a high-definition radiometric NIR-borescope specifically designed for optimal performance at elevated temperature wavelengths (~1 µm). It employs the latest solid-state imaging technology and offers:

• High spatial resolution (3 million pixels) for detailed visualisation.

• Highly accurate, non-contact temperature monitoring with excellent repeatability (standard measured accuracy of 1% of span).

• Dynamic performance with frame rates suitable for most furnace processes, allowing real-time issue detection and thermal sequence recording at up to 15Hz in 2K definition.

In contrast, visual cameras provide no reliable temperature data and cannot visualize create isotherms, process anomalies due to cold/hot spot, or early-stage failures.

Flame Imaging and Hot Exhaust Gas impact

A key advantage of

LAND’s NIR-b-2K HD is its immunity to combustion flames and exhaust gas flows, especially in oxy-gas furnace technology. Typically, temperature data is recorded during flame-off periods in regenerative furnaces, allowing comparison with handheld pyrometers (e.g., Cyclops C 100) for optical thermal profiling.

This capability enables clear thermal imaging of:

• Refractory temperature detection, including hot and cold spots.

• Furnace wall and crown temperatures.

• Batch line locations versus hot spots on thermal profiles.

• Batch pile coverage.

Visual cameras struggle under these conditions due to flame luminosity and gas turbulence, which reduce visibility and diagnostic reliability. This also applies to stoichiometric or oxygen-gas flame burners, where visual cameras cannot provide repeatable thermal distribution data.

Performance in Harsh Environments

The

NIR-b-2K HD is built for durability:

• Operates in ambient temperatures as high as 1800°C.

• Protected by water-cooled jackets and a pneumatic extraction system to prevent overheating, designed for high reliability (LPAR).

• Enhanced air purge system for lens cooling and cleaning.

• Resistant to dust and debris, with a robust extract system design (LPAR or PAR pneumatic auto-extract).

Visual systems often lack adequate cooling or lens purge solutions, making them more vulnerable to contamination and reducing their lifespan in similar conditions.

Operational Advantages

Early Fault Detection: The NIR-b-2K HD enables operators to:

• Detect refractory damage or wear (e.g., overheating, NaOH condensation, rat holes).

• Identify misaligned burners or incorrect airflow to maintain optimal combustion ratios.

• Detect air ingress.

These capabilities support predictive maintenance, reducing unexpected downtime and enabling proactive repairs.

Process Optimisation: Real-time temperature monitoring allows operators to:

• Adjust burners for complete combustion.

• Balance furnace heating.

• Reduce energy consumption.

• Improve product quality and increase production efficiency.

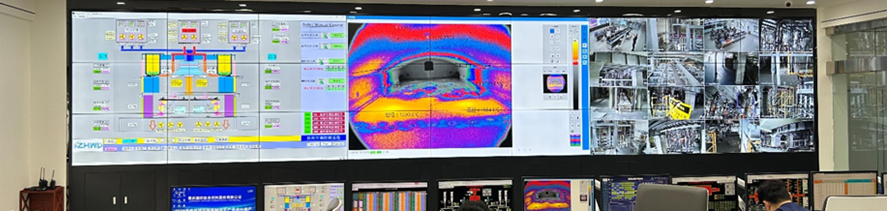

System Integration: The LAND

NIR-b-2K HD integrates seamlessly with plant infrastructure:

• Outputs radiometric data compatible with communication standards (OPC UA, Modbus) for PLC or SCADA integration.

• Supports alarm states, and thermal limits.

• Works with LAND’s ImagePro software for post-analysis, image interpretation, and process audits.

Visual systems lack such integration and rely on subjective video interpretation.

Application Areas

NIR-borescopes, particularly the LAND NIR-b-2K HD, are effective in various furnace environments:

• Glass: Container, float, and fibreglass.

• Paints and Coatings: Decorative, industrial, and marine.

• Steel: Reheat, forging, and annealing furnaces.

• Petrochemicals: Process heaters and reformers.

• Cement and Lime: Kilns and clinker coolers.

• Energy: Factory boilers and waste incinerators.

These applications require high-resolution, flame-penetrating thermal imaging—precisely what the NIR-b-2K HD or MWIR-b 640 delivers. LAND offers advanced IR technology products for applications ranging from 50°C to 1800°C, covering wavelengths from 1 µm to 3.9 µm (MWIR borescopes).

Conclusion

While visual cameras still provide basic visual displays, they fall short in temperature monitoring, flame detection, and durability for advanced furnace diagnostics. In contrast, NIR-borescopes, especially high-definition systems like

LAND’s

NIR-b-2K HD., offer transformative benefits in real-time thermal imaging, predictive maintenance, and process control.

As industry moves towards digitalisation, efficiency, and decarbonisation, the powerful NIR-b-2K HD will play an increasingly vital role in operational strategy and asset management.