We’ve been working for over a decade now on the steam cracking process, a cornerstone of the petrochemical industry. These giant furnaces break down hydrocarbons like naphtha and ethane into valuable products such as ethylene and propylene.

The efficiency of steam cracker furnaces, which operate at extreme temperatures, is critical for maximising output, reducing fuel consumption, and minimising emissions. One innovative method for optimising these furnaces is through thermal imaging to monitor coil temperature profiles continuously and digitally.

The Role of Steam Cracker Furnaces

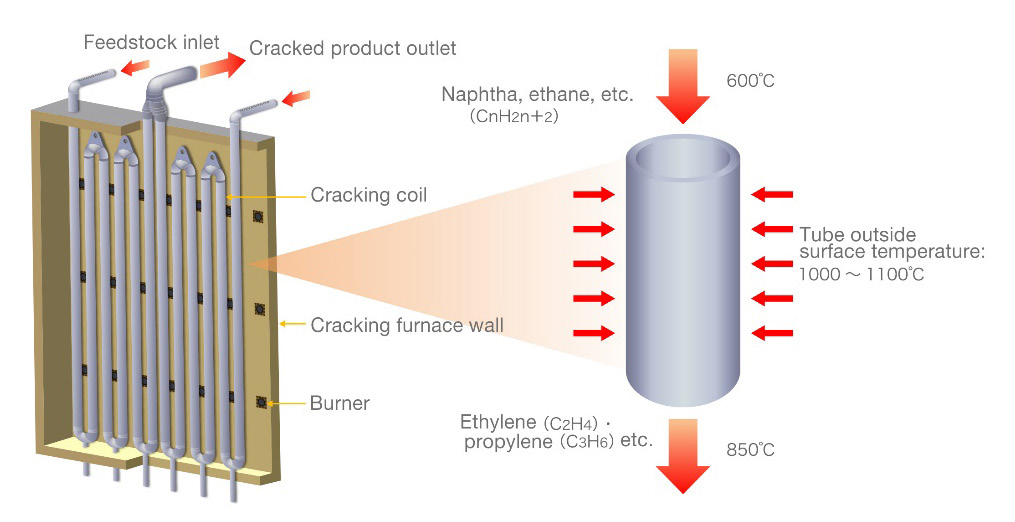

Steam cracker furnaces consist of a firebox housing coils where a mixture of steam and hydrocarbons flows. The firebox typically operates around 1200°C, transferring heat to coils mainly via radiation. Accurate temperature monitoring is vital from a process optimisation and reliability perspective.

Fig 1.

The main components in a steam cracker furnace relating to temperature. Image courtesy of Kubota.

Current Monitoring Limitations

Operators rely on temperature and other process data from distributed control systems (DCS) to monitor furnace status. This includes metrics such as:

•

Feedstock flow rates.

•

Coil inlet, outlet, and firebox pressures.

•

Steam-to-hydrocarbon ratios.

•

Limited real-time temperature data, such as flue gas and Coil Outlet Temperatures (COT).

•

Tube Metal Temperatures (TMTs) gathered manually using infrared pyrometers.

Addressing Coking Challenges

Addressing Coking Challenges

Over time, coke forms on the inside surfaces of tubes, increasing TMT and the differential pressure between coil inlet and outlet. When TMT reaches a predefined limit, furnaces require decoking, a process involving the removal of coke by gasification using steam. Optimising this process minimises downtime and extends furnace life.

Thermal Imaging: The Game-Changer

Thermal imaging systems enable continuous monitoring of TMTs across the furnace. This technology offers several key benefits:

1.

Extended Run Lengths

Accurate, comprehensive TMT data helps operators control temperatures and plan decoking intervals predictively based on real-time data versus highly conservative preventive schedules. This extends run lengths, enhancing furnace productivity and profitability.

2.

Optimised Decoking

Thermal imaging accelerates decoking by providing detailed data across coils to facilitate close control of steam flows that improve decoking whilst avoiding thermal excursions.

3.

Enhanced Coil Reliability

Reducing thermal shocks and high temperature events extends coil life by reducing creep. Proper monitoring helps maintain the designed service life of furnace coils.

4.

Improved Fuel Efficiency and CO2 Reduction

By enhancing heat flux uniformity and reducing decoking frequency, thermal imaging decreases fuel usage and CO2 emissions.

The LAND Solution

The

NIR-B-640-EX and

NIR-B-2K cameras are fixed radiometric borescope cameras for hazardous and non-hazardous areas. Our

IMAGEPro Software analyses temperature profiles, provides historical playback, and integrates with DCS for automated alerts. Deploying thermal imaging cameras requires detailed planning:

Camera Placement:

Camera Placement: Determined via 3D modelling of furnace interiors and exteriors to ensure optimal coverage and accessibility.

Cooling Systems: Cameras require reliable cooling using air, nitrogen, or water, depending on site conditions.

Field Verification: Ensures alignment with OSHA safety standards and operational requirements.

When properly planned and executed with relevant experience and know-how, thermal imaging revolutionises the operation and optimisation of steam cracker furnaces, improving safety, efficiency, and profitability.

With cameras installed on steam crackers worldwide,

LAND’s solutions showcase the true potential of infrared technology in the

petrochemical industry.