In applications where non-contact temperature measurement technology is used, there is occasionally a need for a comparative temperature measurement or a so-called reference temperature measurement to check and confirm the accuracy and plausibility of the process temperature measurements.

In order to carry out such comparative measurements successfully, some boundary conditions must be met in order to address larger deviations in the measured values.

In principle, it can be assumed that all devices for non-contact infrared temperature measurement are calibrated and adjusted in accordance with the applicable standards and rules so that they deliver the same measurement results under laboratory and calibration conditions within their specifications. To do this, it is necessary to regularly check measuring devices such as pyrometers, infrared scanners or thermal imagers and to use the calibration service provided by the manufacturer's.

LAND offers an AMECare Calibration and Servicing, which is offered in different configurations.

The AMECare service guarantees optimal performance, approved quality meeting ISO 9001 standards and much more in order to maintain the relevant measurement technology.

Such calibrations are carried out under laboratory conditions, which are typically not present in real applications. However, it is necessary that the temperature measuring devices used are based on this standard and process measurements are carried out on this basis.

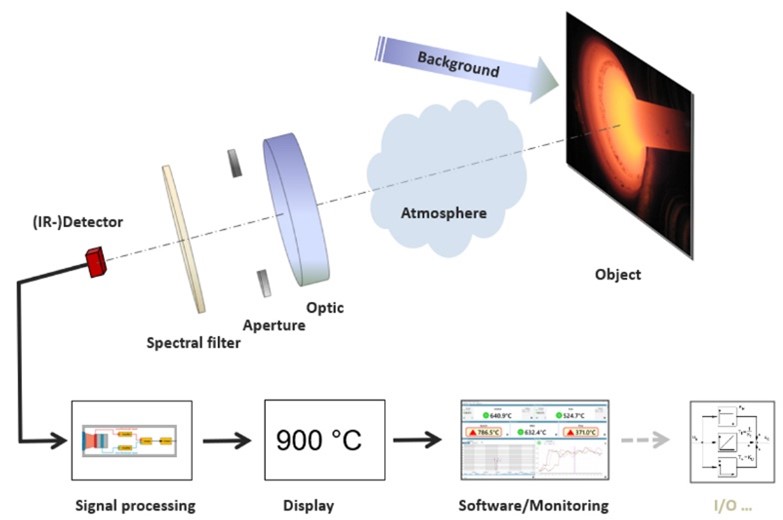

It is important to note what a non-contact temperature measurement can influence. If you follow the radiometric chain (see sketch), a measurement object emits specific infrared radiation, the emitted radiation depends on the measured object, its surface quality and the environmental conditions. Influences such as possible reflections on the surface of the measurement object, for example background reflections with higher temperatures, the atmosphere between the measurement object, for example in furnace atmospheres, the spectral response, the observation angle, the measuring field size or pixel resolution - the so-called field of view (FOV) - and of course the material and its properties themselves can affect the measurement result, too.

Object surface and surface condition of the material

Object surface and surface condition of the material

The picture shows a steel strip in a cold rolling application. Even visible light is clearly reflected on the shiny metal surface. This shiny surface results in a high reflection in the infrared spectral range too. In most cases the higher the reflectivity of a surface, the lower its emissivity as most objects don’t transmit visible or infrared radiation.

Wavelength or spectral response

Wavelength or spectral response

Glass, as an example, does transmit, emit and reflect in different spectral ranges in the visible and the infrared spectra. Depending on the wavelength, it can have a high emissivity and a low reflection. While no transmission (non-ultra-thin glass) around 5 μm wavelength, and at 1 μm it is nearly transparent with a very low emission and reflection. The object emissivity varies with the wavelength.

Viewing Angle

Viewing Angle

The picture of a lake shows the different transmission and reflection behaviour of light. At the bottom right of the picture, the lake ground, covered with stones, is clearly seen – the light is transmitted. While looking further to the lake surface, the mountains in the background are clearly reflected. By changing the viewing angle, the reflectivity, transmission and the emissivity changes.

Temperature

Temperature

While there can be an emissivity change of materials with temperature, especially when undergoing state change, e.g. from solid to liquid, the emissivity changes with the temperature. A large change in emissivity occurs when a material changes state.

There are some rules that need to be considered if carrying out a comparative measurement or a reference measurement using the same measuring method.

- Ideally, the same pyrometer should be used, or at least devices that measure in the same spectral range.

- The measuring field and the measuring field size on the measurement object should be the same size and the device should have the same optics and the same imaging ratio / FOV.

- The distance to the measuring object should be the same.

- The observation angle and the measuring position should match.

- The environmental conditions and timing for measurement should be the same.

- The measuring devices used should have a valid calibration.

The measurement error or measurement deviation specified by the specifications must also be considered. Some specifications show a measurement accuracy that is further specified, e.g. in the footnotes of the specifications.

All information on measurement accuracy is given under laboratory conditions and shown as ± data. For example the same value can deviate upwards (+) and downwards (-).

As an example, if a measurement accuracy of ±0.25% K or 2 K** is given (**Measurements within specification over 5-95% of range) and the measurement is carried out at a measuring temperature of 1000 °C, this means:

±0.25% K results in 997.5 °C – 1002.5 °C with an assumed object temperature of 1000 °C. And or 2 K means that the higher value is the valid value for the measurement accuracy. In this case the value for ±0.25% K is higher than the specified 2 K.

Comparing two measurements from two pyrometers in compliance with the above conditions, it is permissible within the specifications for one to measure at the upper limit and one at the lower limit. In the example, this would lead to a maximal theoretical deviation of 5 K.

In addition there may be additional deviations caused by environmental conditions, such as steam or smoke in the optical path, as well as changes in the surface or emissivity of the measuring surface or reflections from the environment, which are ideally the same for both measuring devices.

SUMMARY

In applications in which a comparative measurement or a reference measurement is to be carried out, some requirements must be considered in order to carry out an actual comparison. The measuring devices or pyrometers used should also have a valid calibration or have been previously checked as part of an AMECare service.

For further questions and support or to request an AMECare service, please click here