To obtain the best temperature measurements of tube walls, there are a number of recommended practices to take into consideration:

Emissivity

Emissivity

The emissivity setting during recording should be set to 1.0. An emissivity correction factor can then be applied manually during the analysis of the data. If the emissivity setting is at a value other than 1.0, the measured temperature will exceed the true TWT, inflating the measured readings and so imposing an artificial limit on the plant.

Background Measurements

Suitable background measurements must be made for every tube from which a temperature reading is taken. These background readings ought to include all the hotter surfaces that are visible to the tube and so likely to radiate to the optical pyrometer. Example surfaces include the side and end wall refractory, furnace roof and flue gas extraction tunnels. For an accurate TWT correction, between 10 and 15 background readings are required.

The number of correction readings taken should be scaled so as to replicate reality. For example, when taking bottom temperature correction readings for a top-fired furnace, more readings should be taken for the flue gas extraction tunnels, as these will contribute more background heat to the TWT than the end walls.

When the bottom peephole is below the tunnel tops, then the background readings should be taken from the tunnel walls and furnace floor. When the hole is above the tunnel tops, then the top of the tunnels should be measured at a ratio of four top measurements to every one taken of the furnace floor, since the floor also contributes to the radiation measured by the pyrometer.

Positioning

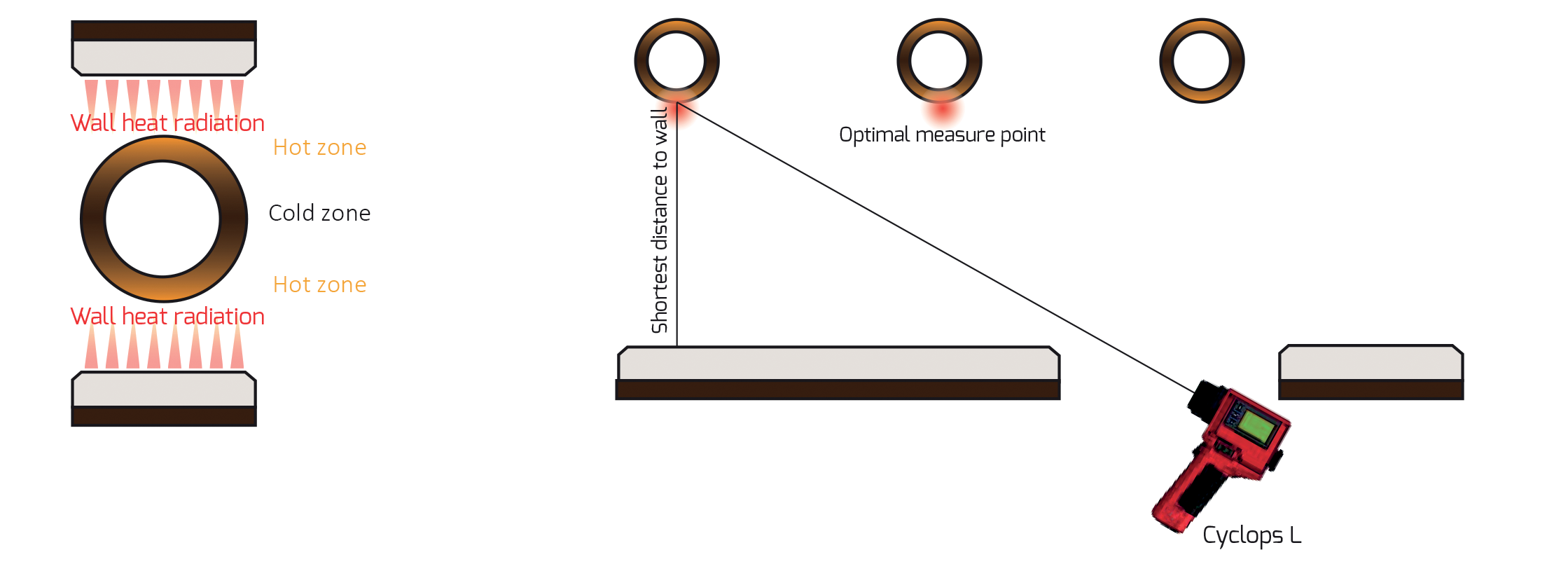

It is, of course, important to avoid picking up any flame temperatures when making either TWT or background temperature measurements, as these will result in much higher readings. Where possible, any temperature readings should be taken at a 90° angle to the tube wall. This minimises the path length, which in turn minimises the effect of the radiation emitted by the combustion gases. The pyrometer should also be placed as close as possible to the peephole, to reduce the effects of the ambient surroundings, and must be held in a constant position to obtain a uniform reading.

Opening Peephole

The time for which the peephole door is open for measurements should be as short as possible, to ensure that the temperature within the furnace does not fall during the measurement shoot. In addition, only one peephole should be opened at a time, to prevent the possibility of a draught circulation effect. Whenever a peephole is first opened, personnel should stand to one side for several seconds, since pockets of higher pressure within the furnace may cause flames to be emitted through the peephole.

AMETEK Land Cyclops L portable handheld pyrometers are used extensively by steam reformer operators and when used in combination with a suitable correction method to allow for background radiation are a reliable and accurate technique for taking TWT measurements.