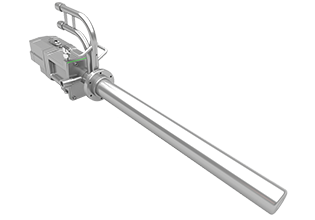

In my previous blog from last month, we discussed the benefits of employing two thermal imaging NIR-B-2K cameras on a container glass furnace. Today, we'll delve into a similar approach for larger float glass furnaces, typically regenerative in nature.

Float furnaces are generally quite substantial, ranging from 600 to 1200 tons per day (tpd), and offer numerous possible locations for mounting

NIR-B-2K thermal imaging cameras. As is often the case, one camera alone cannot capture everything. Ideally, two thermal NIR-Borescopes, one at each end, would be optimal. However, we must consider finite resources.

Historically, float glass furnaces relied on visual cameras placed on both the left-hand side (LHS) and right-hand side (RHS) of the charging area to observe batch pile coverage and determine the batch line's location. However, these methods had limitations. The introduction of thermal NIR-B cameras has significantly enhanced operational capabilities and asset protection.

Float furnaces are typically cross-fired regenerative furnaces equipped with multiple ports (typically ranging from 6 to 9, depending on the tpd production). Our experience includes conducting numerous trials and thermal surveys using a transportable NIR-B, confirming the best-suited locations for

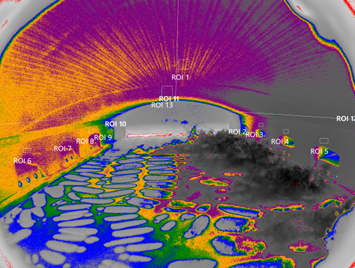

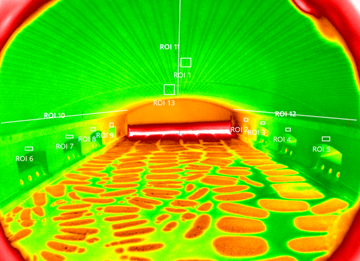

NIR-B-2K cameras and their respective angles. We accomplished this by inserting a transportable NIR-B into various peepholes to observe flames, superstructures, the crown, side walls, charging side, ports, and regenerators.

Through these efforts, we gathered a wealth of information, supported by images. We have compared these results, recognising that NIR-B-2K cameras provide high-definition thermal imaging with precise and repeatable temperature measurements. Our overarching goal remains to maximise pull rates, extend furnace life, minimise energy consumption, reduce emissions, and maintain safety.

When a furnace is new, achieving the desired pull rates, NOx emissions, and energy efficiency is feasible. However, key stakeholders may have different objectives.

NIR-B-2K cameras are implemented to support the entire furnace team, providing critical data on regenerator health (a crucial factor for achieving maximum pull rates), detecting damaged areas, pinpointing hot and cold spots, aligning the batch line with thermal profiles, and optimising energy consumption to reduce emissions.

On larger furnaces, increasing the number of NIR-B-2K camera locations enhances data collection, including thermal images, resulting in improved glass quality and higher pull rates.

AMETEK Land's NIR-B-2K (High-Definition Near Infrared cameras) are employed on float glass furnaces for specific reasons, primarily to enhance operations. While two cameras are ideal, even four would be considered optimal. We recommend using two NIR-Bs, positioned along the centerline of the furnace, one on the back wall and one on the front wall's opposite side. This configuration optimises capital expenditure while providing an excellent view of the charging side, allowing for batch line location assessment and observation of all port sides and flame shapes.

During reversals, the crown's temperature distribution can be monitored on the opposite side, allowing for the identification of hot spots and thermal profiling of side walls, ports, and the crown.

Additionally, the use of multiple NIR-B-2K cameras offers potential benefits:

Temperature Profiling: Float glass furnaces operate at extremely high temperatures, and multiple thermal imaging systems create comprehensive temperature profiles. This enables operators to identify hot spots, cold spots, and areas with uneven temperature distribution, ensuring consistent glass quality and maximising pull rates.

Furnace Life Extension: Monitoring temperature distribution helps prevent localised overheating, which can lead to structural damage and reduced furnace lifespan. Early detection extends operational life.

Combustion Optimisation: Efficient combustion is crucial for energy savings and emissions reduction. Thermal imaging aids in optimising combustion efficiency by visualising the process and adjusting parameters such as burner positioning, air-fuel ratios, and flame patterns. This can significantly reduce energy consumption, NOx, and CO2 emissions.

Preventative Maintenance: Early detection of hot spots or batch patterns allows proactive maintenance scheduling, minimising downtime and production losses.

Consistent Quality: Maintaining uniform temperatures across the furnace ensures consistent glass quality and reduces defects, saving on material and production costs.

Safety Assurance: Continuous thermal monitoring ensures safe temperature ranges, reducing the risk of accidents and catastrophic failures.

Long-Term Data Analysis: Thermal imaging systems provide historical data for analysing long-term trends and making informed decisions about process improvements and maintenance plans.

In conclusion, utilising two

AMETEK Land NIR-B cameras on float glass furnaces enhances temperature control, improves safety, increases efficiency, and contributes to maintaining high-quality glass production. The next logical step, especially for large furnaces with a 1200tpd glass production capacity, is to consider deploying multiple NIR-B-2K cameras for even more precise thermal control.