Thermal imaging is already revolutionising the way we inspect and monitor industrial processes, especially high temperature furnaces/fired heaters, where a small temperature excursion can have a big impact on the rate of coking and ultimately the tube's lifetime. In a few recent examples, we've started to see that higher definition cameras are able to detect very local/small hot spots and anomalies.

See two examples below. The first example shows a standard definition camera's view of a row of burners. Whilst the camera is able to detect differences in temperatures between burners (serving a key purpose), the high-definition camera is able to detect a very high, highly localised elevated temperature.

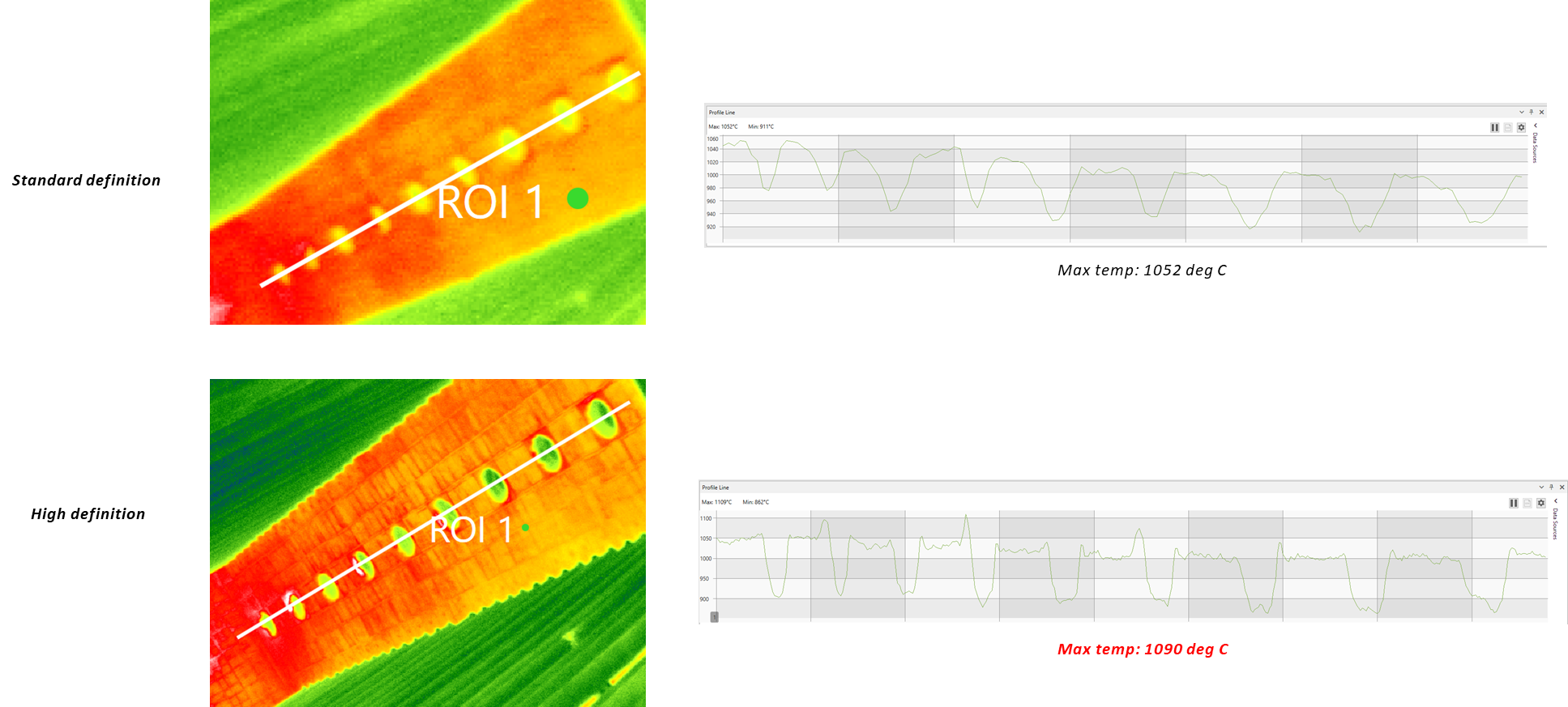

The second example shows a similar phenomenon applied to a hot spot on a tube. The increased spatial resolution means the camera can detect closer to the peak temperature of the hot spot, in this case resulting in a higher maximum temperature. A standard definition camera may have shown the hot spot, but the higher definition camera shows the tube running over its design temperature, albeit in a small area.

Example 1:

Example 2:

The advantages can be broken down into three main areas:

Increased Spatial Resolution:

Higher definition thermal imagers have superior spatial resolution. Traditional thermal cameras may provide an overview of furnace temperatures, but with higher definition sensors, we can use wide angle lenses to capture comprehensive temperature data in a single scene, where previously a standard camera may have been used with a zoom lens. This means that even small temperature variations, which might indicate potential issues, can be accurately detected and analysed. From worn-out refractory lining to faulty burners, the enhanced spatial resolution empowers maintenance teams to pinpoint anomalies at their early stages before they escalate into critical problems.

Improved Sensitivity:

Higher definition sensors also have improved temperature sensitivity. Greater sensitivity to tiny temperature deltas and changes means that it is possible to discern subtle variations in the furnace. This level of sensitivity is essential for detecting anomalies like hotspots, cold spots, and uneven heat distribution, which can be indicative of issues such as fouled burner tips, or damaged burner tiles and refractory .

Enhanced Image Quality:

High-quality thermal images make it easier for inspection and maintenance teams to share and emphasise specific findings with other key stakeholders. The ability to highlight and show high resolution/contrast snapshots with 10x the number of pixels over standard imagers helps to communicate the urgency of action around elevated temperatures. As AI tools and smart furnace technology enters the marketplace, advanced image processing techniques and data analytics will be applied to these images and their associated datapoints, enabling automated anomaly detection algorithms that further streamline the inspection process.

By continuously (with a fixed cameras) or periodically (with a portable camera) monitoring the furnace's temperature changes over time, patterns and trends can be identified, allowing maintenance and operations teams to anticipate and proactively address potential issues before they cause upsets, disruptions or safety issues.