The temperature in the burning zone can be as high as 1450 °C (2940 °F) but the kiln’s steel shell has a maximum practical temperature below 500 °C (932 °F). As a result, it needs to be protected from the hot feed and the gases within by a thick layer of refractory bricks.

These refractory bricks have a low thermal conductivity that protects the

kiln shell. They are also used for their physical stability and resistance to abrasion as well as the highly basic chemistry of the clinker. Over time, chemical changes in the surface of the refractory bricks can lead to spalling, which means the bricks will rapidly deteriorate if they’re exposed to overheating in the burning zone.

Sudden mechanical damage is also possible, especially if the kiln shell distorts because of uneven rotation. Whatever the underlying cause may be, deterioration of refractory bricks reduces their insulating properties and causes an increase in the kiln shell temperature. Measuring the shell temperature, therefore, allows the operator to monitor any long-term changes in the refractory and detect loss or damage to individual refractory bricks.

There are several methods for measuring the

kiln shell temperature. Point measurements can be made using thermocouples with wireless transmitters, but it is impractical to install enough sensors to detect the condition of individual refractory bricks.

A handheld pyrometer can be used to make repeated measurements with good coverage, but the results depend on the skill of the operator and, obviously, real-time measurements are not possible.

A handheld thermal imager allows the operator to visualize the kiln shell and identify hot spots, but it is also non-continuous and requires a skilled operator to interpret the data.

The ideal is to have a continuous method that delivers a high-resolution and accurate temperature map of the kiln surface. A fixed industrial thermal imager can provide an image of the kiln, but conventional imagers do not provide accurate temperature measurements. A radiometric thermal imager is therefore needed for this application. High resolution is needed, especially for long kilns. If a 70 m (230 ft) long kiln fills its field of view, a 640 x 480-pixel imager such as AMETEK Land's

LWIR-640 can provide a pixel resolution of 110 mm (4.3 in) which is comparable in size to an individual refractory brick.

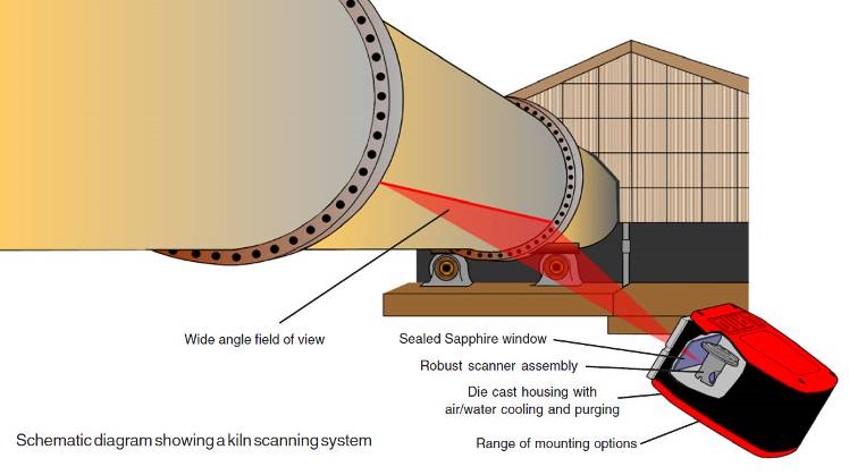

A line-scanning infrared sensor such as the

LSP-HD can achieve even higher resolution. This device uses a single detector with a scanning mirror to repeatedly scan along the length of the kiln, giving the equivalent of 1,000 pixels along the kiln.

The rotation of the kiln allows the scanner to build up a complete image of the

kiln shell. Using a single sensor allows for excellent consistency of measurement when compared to a thermal imager. Even the best image sensors exhibit considerable pixel-to-pixel variability, whereas the scanner uses the same sensor for every point in the measurement.

When using this technique, it is important to limit the scan angle to 90° or less. A wider angle allows the scanner to be mounted closer to the kiln, but the surface emissivity of the kiln decreases rapidly at high angles, and the imaged spots become very elliptical, leading to reduced accuracy and degraded spatial resolution.

If it is not possible to set the scanner or imager sufficiently far away to obtain a full view of the kiln, image processing software can stitch the output of multiple devices to give a single display. This approach also allows enhanced spatial resolution, as it effectively doubles the number of pixels in each scan.

Modern temperature measurement techniques provide many insights into all aspects of the cement kiln operation, allowing for improvements to product quality, reduced fuel consumption and improved reliability. A high-resolution radiometric thermal imager or linescanner can provide essential information about the shell temperature and the condition of the refractory bricks.

Click here to download our cement application note.