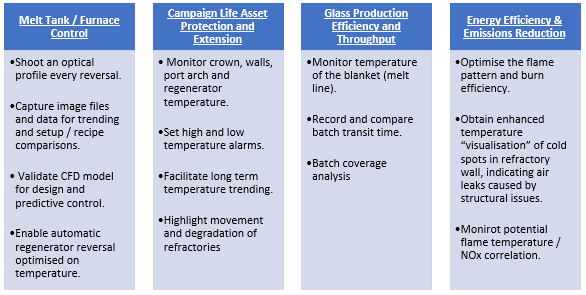

The benefits of accurate real-time temperature measurement in a glass melt tank or furnace can be explained based on four core pillars:

- Melt tank / furnace control

- Campaign life asset production and extension

- Glass production efficiency and throughput

- Energy efficiency and emissions reduction

As a leading provider of technologies for temperature measurement and combustion monitoring, our innovative NIR-B-2K is a high-resolution short-wavelength radiometric infrared borescope imaging camera designed for a wide range of continuous process monitoring and control applications and offers extensive benefits for glass melt tank/furnace operations.

When using our near infrared borescope thermal imaging system, coupled with our powerful IMAGEPro image processing software, each of these pillars offers many valuable benefits to a glass plant.

These benefits can be extended further to include digitalisation of thermal distribution with fully inclusive thermal imagery for distributed control system data analysis, simple batch control and analysis, combustion and flames optimisation for improved heat balance, and importantly full traceability of data for quality management.

Find out more about our latest NIR-Borescope-2K-Glass high definition thermal imaging system, delivering nearly 3 million temperature points, for glass furnace applications here.