One of the most critical factors in achieving high-quality aluminium is maintaining the correct temperature of the molten aluminium during the melting and pouring process.

If the temperature is

too high, the chemical and physical properties of the metal can change, leading to castings that fail to meet specifications.

If the temperature is

too low, the metal may begin to solidify prematurely, preventing it from fully filling the mould and resulting in defects.

Consistent temperature control during the tapping process is essential to ensure the final product is of the highest quality.

The Challenge of Measuring Liquid Aluminium

Liquid aluminium reacts quickly with atmospheric oxygen, forming an oxide layer on its surface. In static environments like furnaces or ladles, this layer thickens and may form crust-like deposits on the surface, especially in furnaces or ladles.

However, during dynamic processes, such as tapping or when the melt is induction-heated, the oxide layer remains thin, and the surface of the liquid aluminium behaves like a mirror, reflecting nearly all radiation and changing quickly.

This reflective nature makes accurate temperature measurement particularly challenging during tapping, where traditional methods like thermocouples often fall short.

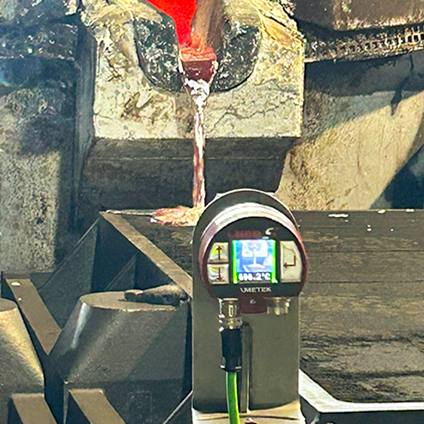

The Solution: SPOT+ AL Pyrometer with L-Mode

To overcome these challenges,

LAND has developed the

SPOT+ AL Aluminium Application Pyrometer, featuring a specialised L-mode algorithm designed specifically for liquid aluminium.

This advanced pyrometer enables reliable, real-time temperature measurement during the tapping process.

By simply selecting the appropriate application mode, operators can monitor and control the temperature of the aluminium melt as it’s transferred into ladles or moulds, ensuring optimal casting conditions.

Customer Experience and Benefits

“Accurate temperature measurement of liquid aluminium is key to ensure process efficiency and product quality of the castings. This technology from LAND is new to the industry and can achieve results that were previously not possible with traditional thermocouples.”

This feedback highlights the transformative impact of the

SPOT+ AL in aluminium production processes, offering a level of precision and reliability that conventional methods cannot match.

Why Choose LAND?

With decades of experience and a global reputation for excellence,

LAND works closely with leading aluminium producers to deliver tailored solutions for every stage of the production process.

LAND’s products combine precision, speed, and robust performance, backed by expert support and service to keep your operations running smoothly.

Learn more about the SPOT+ AL Pyrometer for aluminium production and processing.