LAND has released a new application note providing guidance for manufacturers on improving temperature control in the blown film extrusion process.

This critical stage of plastic film production determines the final product’s thickness, clarity and strength, making accurate temperature control essential.

The

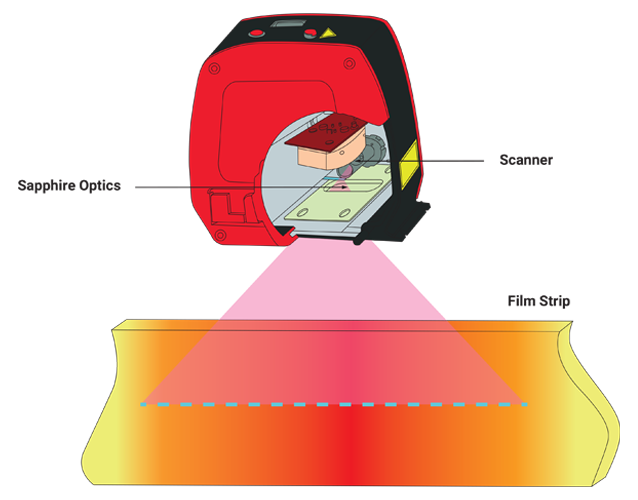

application note highlights how the

LSP-HD 60 infrared linescanner and

SPOT+ M3-5 pyrometer can be used together to provide comprehensive thermal monitoring.

This approach offers high-definition temperature data from the die exit and bubble expansion, through the frost line, to the collapsing frame, helping operators identify uneven cooling and fine-tune process parameters.

The

LSP-HD 60 captures 1,000 samples per line at scan speeds up to 150 Hz, delivering detailed thermal images with temperature sensitivity below 0.5 °C. This creates a heat map that helps manufacturers track temperature changes over time and distance, and maintain a consistent frost point.

The

SPOT+ M3-5 complements the linescanner by monitoring low-temperature zones throughout the extrusion line. Its compact, wireless design makes it easy to install at key points such as the die exit and collapsing frame, providing additional insight into late-stage anomalies.

Using both instruments together gives manufacturers greater visibility of the extrusion process, enabling faster response times, improved product consistency and better cost control.

To download the full application note, click here.