Read about our infrared thermal imaging system, NIR-B 3XR, in the May-June 2019 edition of Nitrogen+Syngas, where our solution for 24/7 monitoring of tube wall temperatures in reformers is discussed as a practice to prevent catalyst tube issues and to allow plants to run at maximum output.

Reformer tubes are highly valuable assets. A large reformer contains hundreds of tubes, at an average tube cost of approximately $15k to $30k each, and unplanned outages can result in significant costs of $350k to $1m a day, so increasing tube life and reducing tube failures is essential asset management. That means having an effective method of temperature measurement.

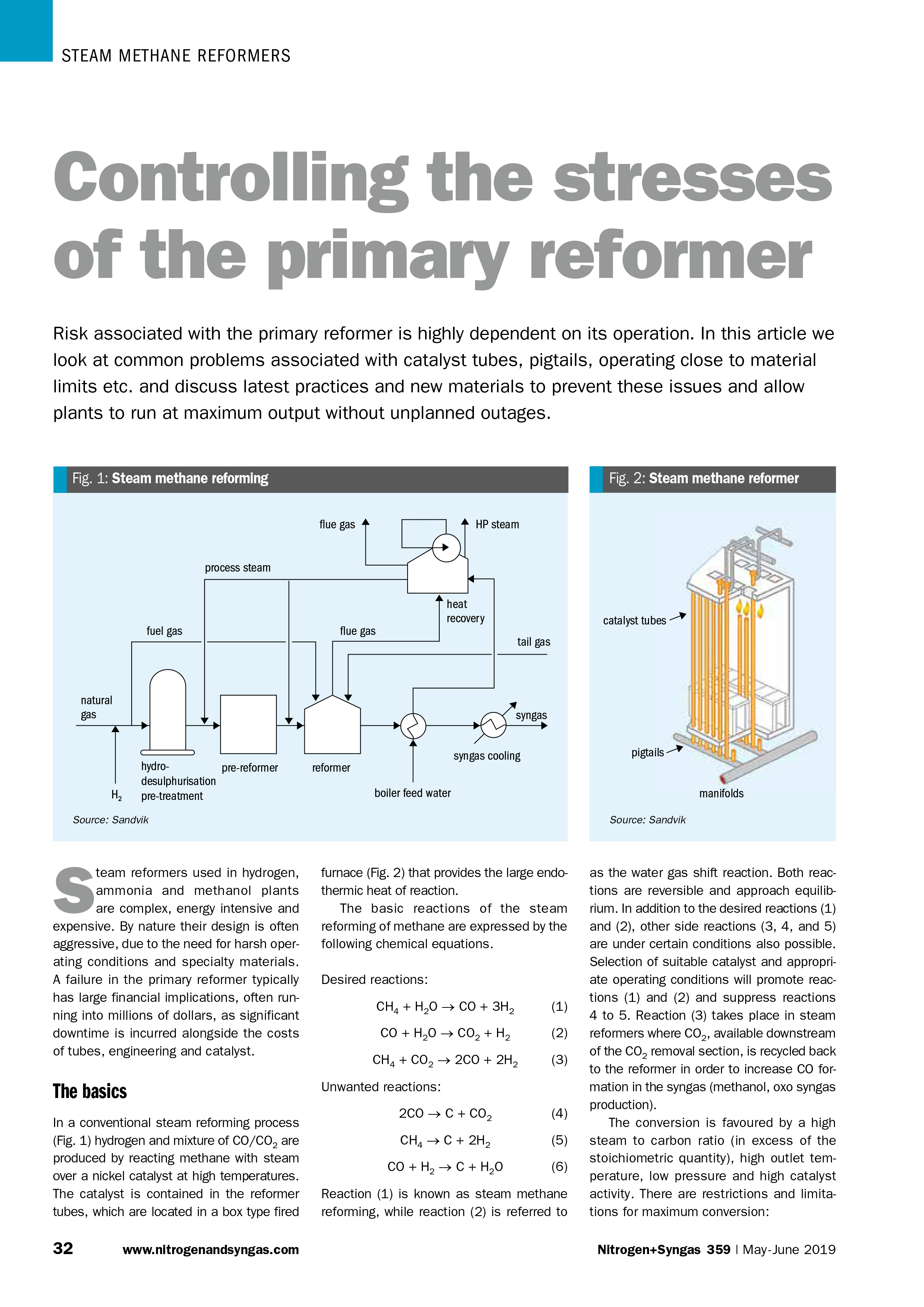

The monitoring of tube wall temperatures (TWT) can help optimise catalyst tube life and ensure longevity, energy efficiency and productivity. With better temperature control, operators can increase profit by increasing output and lowering operating cost, resulting in better utilised feedstock, catalyst and fuel. A 2% improvement in output has the potential to save approximately $1 million a year.

Read the full article in Nitrogen+Syngas - May-June 2019