In copper smelting, even small improvements in metal recovery can have a major impact.

Recovering more valuable metal from every tap not only improves productivity but also supports more efficient use of raw materials and safer working practices.

One critical challenge in smelting operations is knowing exactly when to stop a tap. End it too early and valuable metal is left behind. End it too late and unwanted slag is carried over, increasing reprocessing, waste and cost. Traditionally, this decision has relied heavily on operator judgement and visual observation, a method that can be inconsistent and exposes personnel to extreme temperatures.

Moving beyond manual slag detection

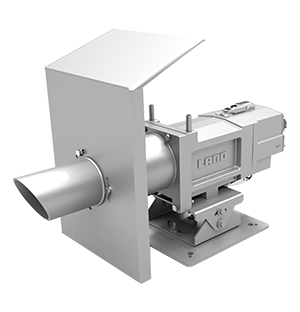

LAND’s

Slag Detection System (SDS) was originally developed for steelmaking applications, where it has been successfully installed in hundreds of plants worldwide. More recently, the same core technology has been adapted to meet the specific demands of copper smelting.

Unlike manual approaches,

SDS provides continuous, automated monitoring of molten material during tapping. Using thermal imaging, the system distinguishes between copper matte and slag in real time, giving operators a clear and objective view of what is flowing from the vessel.

Why thermal imaging works

The key lies in how different materials emit infrared energy. Although molten matte and slag can be at very similar physical temperatures, they behave differently when viewed in the infrared spectrum.

By operating at a carefully selected mid wavelength infrared range, SDS:

- Minimises interference from flue gases, fumes and dust

- Reduces the impact of fine particles that can obscure visible light cameras

- Exploits the natural emissivity contrast between slag and metal

This allows the system to reliably identify when slag content begins to rise, even when the change is subtle and difficult to detect with the naked eye.

Real-time insight for better decisions

During a tap, operators see a live thermal image with clear visual separation between slag and matte. The system continuously analyses the image and calculates the proportion of each material in the stream.

As slag levels increase towards the end of a pour, SDS can alert operators or trigger an automatic stop at a predefined threshold. This consistency removes guesswork and improves repeatability from one tap to the next.

Benefits beyond recovery

While the primary aim is improved metal yield, the benefits go much further:

- Reduced metal losses, leading to higher overall recovery

- Greater operational consistency, independent of individual experience

- Improved safety, as operators no longer need to observe the tap directly

- Lower reprocessing and waste, supporting sustainability goals

Remote monitoring via a control room display significantly reduces exposure to heat, fumes and splash hazards, contributing to a safer working environment.

Supporting more sustainable smelting operations

By increasing the amount of copper recovered from existing material,

slag detection technology helps smelters do more with less. Improved efficiency reduces the need for additional raw materials and lowers the energy required for secondary processing.

As copper producers continue to focus on productivity, safety and environmental responsibility, advanced slag detection offers a practical way to support all three objectives.

If you would like to learn how LAND’s

Slag Detection System can support copper recovery, efficiency and operational safety at your site, our specialists are available to help.

Click here to contact us and discuss your application.