Steel manufacturing is evolving fast.

From digitalisation to decarbonisation, the industry is under pressure to adapt or risk falling behind. To remain resilient, steel producers must embrace innovation and stay informed on developing technologies.

Philippe Kerbois, Global Industry Manager at

LAND, specialising in metals, has shared his thoughts on how technology is shaping the future of steel. Drawing on his decades of experience, Philippe sheds light on the challenges the industry faces and how we’re helping manufacturers overcome them.

How has steel manufacturing changed in the last 30 years?

Fluctuating demand, production costs, and environmental regulations have all brought the long-term sustainability of many steel companies into question. To survive these challenges of the modern market, the industry has become leaner, smarter, and more data driven.

Increasing scrutiny of carbon intensive industries has required extensive reporting and compliance. Meanwhile, the workforce has become fewer but more expert than ever before.

Advancing technology has also changed the steel industry – particularly in temperature measurement. Continuous monitoring and with thermal imaging and automated process control has become central to process optimisation.

Historically, metal production has faced issues like:

1. Slag carryover in steel

2. Crust formation in aluminium furnaces

3. Inconsistent temperature control

These challenges have caused waste and inefficiencies at metal plants for as long as we can all remember.

But our innovations in this area have already made huge bounds towards solving these problems with technologies such as:

1.

Data driven Slag Detection Systems (SDS)

2.

Real-time thermal imaging combined with Imagery software

3.

Multi wavelength emissivity-corrected instruments with SPOT+

Using real-time data to improve performance is fast becoming the industry standard. With this, we see increased demand for digital solutions that tighten process control.

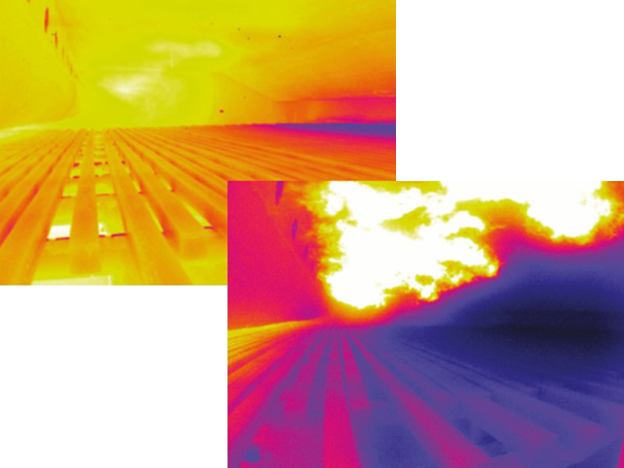

Thermal imaging: how NIR-b and MWIR-b cameras have changed the steel industry

Across each phase of the production process, the steel industry represents some of the most extreme environments in manufacturing. Precision, safety, and efficiency are all critical on a day to day. Errors caused by outdated practices can result in defective products, dangerous equipment malfunctions, and even environmental penalties.

Thermal imaging technology has made it possible to collect in-depth real-time data during production. The adoption of

near infrared (NIR) and

mid-wave infrared (MWIR) borescopes have affected how steelmakers:

• Monitor furnace conditions

• Improve process control

• Ensure worker safety

While they may sound similar, MWIR and NIR borescope imaging cameras serve different purposes on the plant floor.

Mid-wave infrared borescope (MWIR-b)

MWIR-b thermal imaging cameras work in the mid-wave infrared spectrum (around 3 to 5 microns). They capture images of thermal radiation in high-temperature environments. This visual data allows precise temperature mapping of molten steel, refractory linings, and combustion zones.

With MWIR-b imaging, steel plants benefit from:

• Real-time, radiometric temperature readings

• Thermal mapping of molten metal surfaces

or furnace walls

• Process control for Electric Arc Furnaces (EAF), Basic Oxygen Furnaces (BOF), and tapping operations

• Reliable data in visually obstructed environments (e.g., dusty, high-flame)

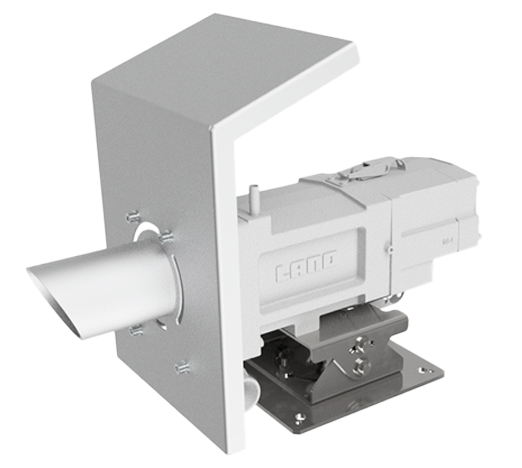

For example, steel tapping requires monitoring of the exact surface temperature of molten steel. This data is essential for yield, safety, and high quality. To achieve this, specialist instruments like LAND’s

MWIR-b-640 deliver consistent and reliable results – even in environments heavy with dust and smoke.

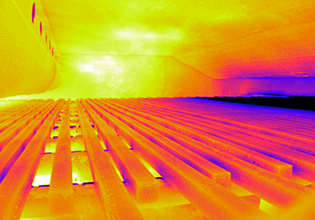

Near-infrared borescope (NIR-b)

NIR-b thermal imaging cameras operate in the near-infrared spectrum (typically 0.78 to 1.4 microns). They are effective for visualising internal furnace structures at high resolutions, even under harsh lighting and high temperatures. You can use it for:

• High-resolution visual monitoring of furnace interiors

• Clear views of flame shape, burner condition, and

refractory structure

• Visual feedback during inspections, maintenance, or process startup

With resolutions up to 3 million pixels,

NIR-b borescopes allow steel producers to analyse performance to the finest detail for continuous improvement.

Learn more about LAND’s solutions for steel

Enhanced safety for workers in the steel industry

The benefits of remote temperature monitoring extend beyond the final product. It also creates a safer work environment by keeping workers further from the furnaces than traditional methods of measurement.

Data is also key to preventing disaster. Furnaces operating at extreme heat create risk. The

World Steel Association reports that fires, explosions, and hot metal were collectively the cause of dozens of deaths between 2019-2023. With continuous real-time data, operators on-site can perform proactive repairs to reduce the likelihood of accidents.

What are the main challenges facing the steel industry in 2025?

Balancing net-zero targets with industrial demand

One of the greatest challenges steel faces today is balancing environmental targets with delivering for its loyal customers across the automotive, construction, energy, and manufacturing sectors.

These end-users depend on your ability to deliver consistent, large-scale supplies. Any disruption or slowdown could have widespread ripple effects. Recognising this challenge, we deliver customisable solutions that integrate with existing systems to minimise disruption.

The transition to green steel

To meet climate commitments while maintaining their competitive edge, steelmakers worldwide are accelerating the shift toward low-emission production. This transition is being driven primarily by two emerging technologies:

1. H2 steel, or hydrogen-based direct reduced iron (H₂-DRI), to produce steel without carbon.

2. Electric arc furnace (EAF) technology to melt scrap steel without coke or coal. EAFs have replaced most basic oxygen furnace in modern steel production.

By adopting these advancements, steel producers can take advantage of:

• Reduced carbon emissions and lower carbon taxes

• Greater energy efficiency in an inherently energy intensive process

• Increased flexibility in feedstock sourcing (scrap or DRI)

At

LAND, we've responded to the demand for sustainable steel with tools to:

• Optimise combustion

• Reduce energy waste

• Monitor thermal losses

Our solutions not only integrate with EAFs and hydrogen steel processes, but they also enhance them by providing data on their performance for continuous improvement.

Global industrial regulations and supply chain reporting

Increasing environmental regulations mean many steelmakers must report on emissions from their entire value chain – known as 'Scope 3’ emissions. As a supplier, falling behind can be a competitive disadvantage when up against more sustainable steel manufacturers.

To keep up with the increasing pressure, operators must keep up with advancing Best Available Techniques (BATs) and continuously look to improve environmental performance.

Adoption of lightweight alloys and recycled materials

The growing use of lightweight alloys and recycled materials poses a real challenge for the steel industry. Unlike traditional raw materials, these inputs don’t behave consistently in extreme conditions.

Without precise thermal control, this variability can lead to quality issues, increased scrap, and costly downtime. As steelmakers aim for efficiency and sustainability, managing this inconsistency with advanced thermal imaging becomes critical.

Utilising customised integration in steel making

In steel production, every part of the process needs to work together. Data that isn’t integrated into your broader system is wasted potential. To find solutions for the challenges steel plants are facing, monitoring technology needs to integrate with the system, not the other way around.

We’re equipped to tackle the toughest challenges in steel production with:

• Proven solutions for extreme environments

• Fully customised system integration

• Global support, service, and training

By integrating our technology into your workflow, our systems deliver thermal data that is insightful, relevant and actionable.

What emerging technology is going to impact steel producers?

The future of technology in steel production is vast with new tools opening doors in predictive process control.

Most notably, AI is the hot topic in industrial data analytics. At LAND, we've continued to advance our range of infrared imaging systems with AI enabled data analytics. Combining real-time analysis with automated extraction systems (like LPAR) not only reduces errors, but also enables your team to focus on more skilled, strategic tasks.

Increased quality of imagery is also expanding what we can do with data. Operators have benefited from a 25% reduction in slag depths using our next-generation

Slag Detection System (SDS V2). With this application-specific thermal imaging solution, operators can achieve improved safety and yields compared to plants without it.

The next leap in thermal imaging technology will be multi-spectrum instruments – advanced infrared cameras capable of detecting multiple parts of the infrared spectrum in a single device. These versatile instruments can adapt for multiple applications, helping drive the next wave of steel.

Looking further ahead, technologies like digital twins, edge-based analytics, and thermal modelling are moving from concept to reality. Integrating them with thermal intelligence will drive smarter, faster, and more energy-efficient operations across steel producers.

LAND in the steel industry

For over 75 years, we’ve been world leaders in industrial infrared temperature measurement. Providing precision performance even in the harshest conditions, our instruments can support every critical stage of the steel production process.

Discover more about how we support the steel industry here.