A new application note from LAND examines the critical role of accurate, non-contact temperature monitoring in drop and press forging processes. It explores how their advanced pyrometers and thermal imaging solutions are improving production, efficiency and process control.

Drop forging uses a forging hammer to produce parts, tools and fittings at high volumes. To achieve consistent results, components are heated in a gas-fired or induction furnace before being moved on to the hammer. Each small, heated part is measured with a pyrometer before forging. Parts outside of the desired temperature range are usually redirected to a separate container. If the temperature data is not accurate, it could lead to unnecessary scrappage and increased production waste and costs.

For these applications, the

SPOT+ Pyrometers from

LAND deliver fast and accurate point temperature measurements as parts move from the furnace to the hammer or press. By detecting out-of-range components instantly, the SPOT+ reduces waste, optimises processes throughout and supports quality standards.

Press forging is used to create large components, such as rolls or shafts, which must be heated multiple times throughout the process. To avoid creating any structural or press damage, materials have a temperature window that must be closely monitored and adhered to throughout the process.

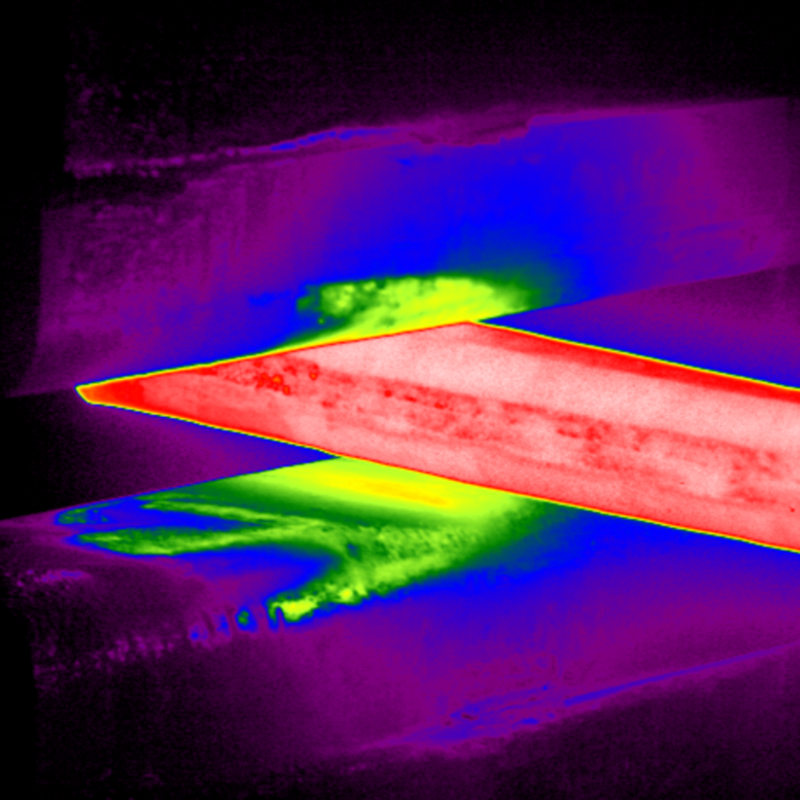

The

NIR-2K and

MWIR-640 thermal imagers from

LAND® continuously monitor parts across their entire surface, detecting hot and cold spots that a single point pyrometer might miss. This ensures consistent process control and avoids costly rework or equipment damage.

Online process control has never been easier, providing remote 24/7 access to process and temperature data. Temperature ranges span from 600 to 1800 °C / 1112 to 3272 ºF (

NIR-2K at 3 million camera pixels) or (300) 500 to 1800 °C / (572) 932 to 3271 °F (

MWIR-640 at > 300.000 camera pixels), both fully radiometric calibrated.

“Forging environments demand precision and reliability,” said

Manfred Hayk, Technical Product and Application Support Manager, at

LAND.

“Our SPOT+ pyrometers and high-resolution thermal imagers give operators complete visibility of temperature conditions, enabling faster decisions, improved quality and reduced waste.”

LAND’s non-contact

temperature measurement technologies can be used for a wide range of applications, including heat treatment, forging and forming. By providing accurate, real-time insights, they help operators improve efficiency and maintain the highest production standards.

To learn more about how temperature measurement solutions from LAND enhance forging processes, read the application note here.