Read our latest article in World Biomass where Derek Stuart, AMETEK Land's Global Product Manager - Power, Combustion and Environmental looks at preventative measures which can be taken to avoid early combustion of biomass pellets.

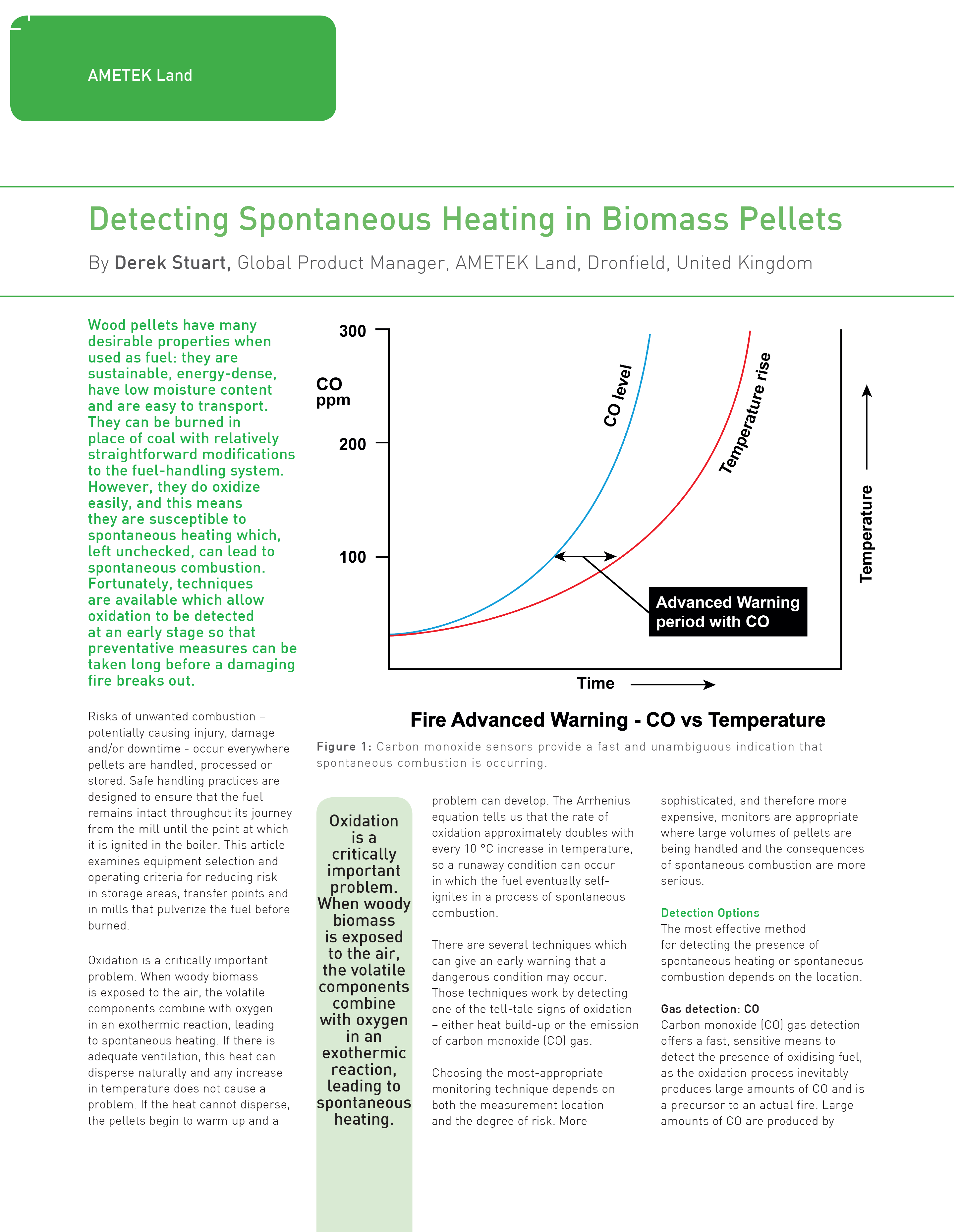

Wood pellets have many desirable properties when used as fuel: they are sustainable, energy-dense, have low moisture content and are easy to transport. They can be burned in place of coal with relatively straightforward modifications to the fuel-handling system. However, they do oxidize easily, and this means they are susceptible to spontaneous heating which, left unchecked, can lead to spontaneous combustion. Fortunately, techniques are available which allow oxidation to be detected at an early stage so that preventative measures can be taken long before a damaging fire breaks out.

Risks of unwanted combustion – potentially causing injury, damage and/or downtime - occur everywhere pellets are handled, processed or stored. Safe handling practices are designed to ensure that the fuel remains intact throughout its journey from the mill until the point at which it is ignited in the boiler. This article examines equipment selection and operating criteria for reducing risk in storage areas, transfer points and in mills that pulverize the fuel before burned.

Read the full article in World Biomass - 2019